Why Choose Us ?

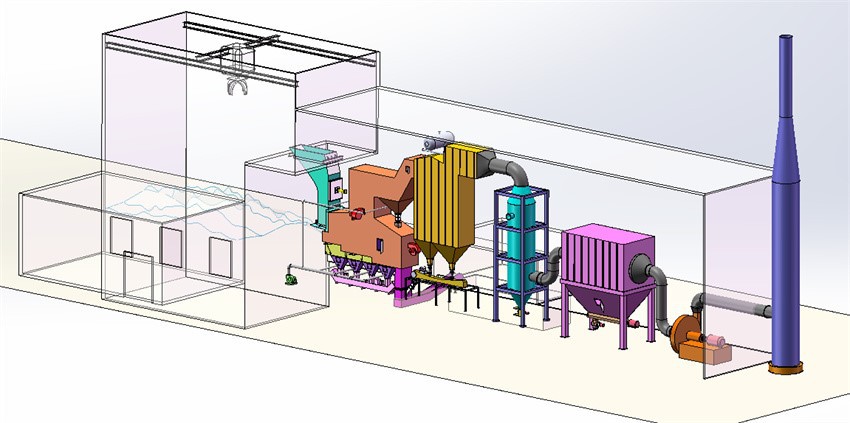

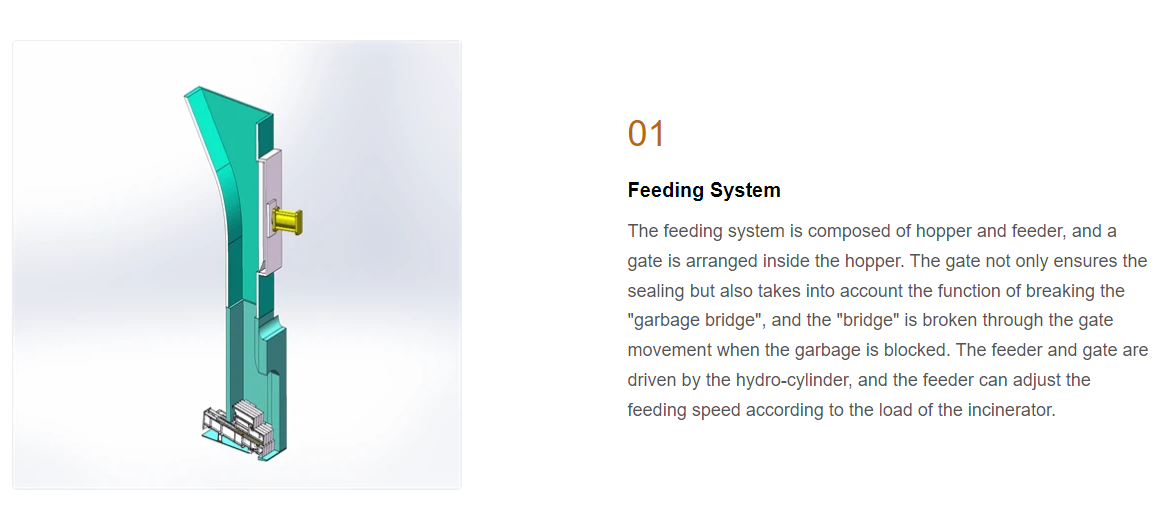

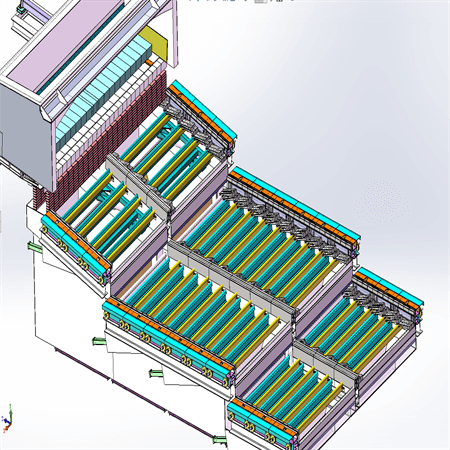

Tenor Low Carbon New Energy Technology Co., Ltd. developed a small waste incineration systems with the research team at Dalian University of Technology. WTE incineration systems include a hopper and feeding machine as well as stoker, step grates, ash hoppers, slag removal systems, transport aircraft, combustion chambers, and slag hoppers.

What is Trash Incinerator Industrial?

waste management facility designed to dispose of waste generated by industrial processes through combustion. These facilities are typically larger and more complex than municipal trash incinerators, as they must handle a wider variety of waste materials and may have higher throughput requirements.

Products Description

Tenor made small waste incineration system was developed by Tenor Low Carbon New Energy Technology (Liaoning) Co., Ltd. and Dalian University of Technology research team. WTE incineration system including hopper, feeding machine, stoker furnace,step grate, ash hopper, slag removal system, transport aircraft and combustion chamber, suitable for daily capacity of 50 to 250 tons/d of small domestic waste incineration projects.

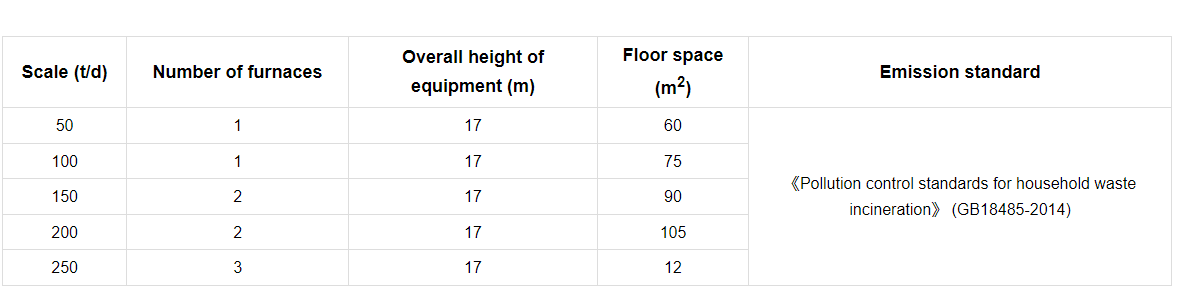

Products Parameters

Main equipment

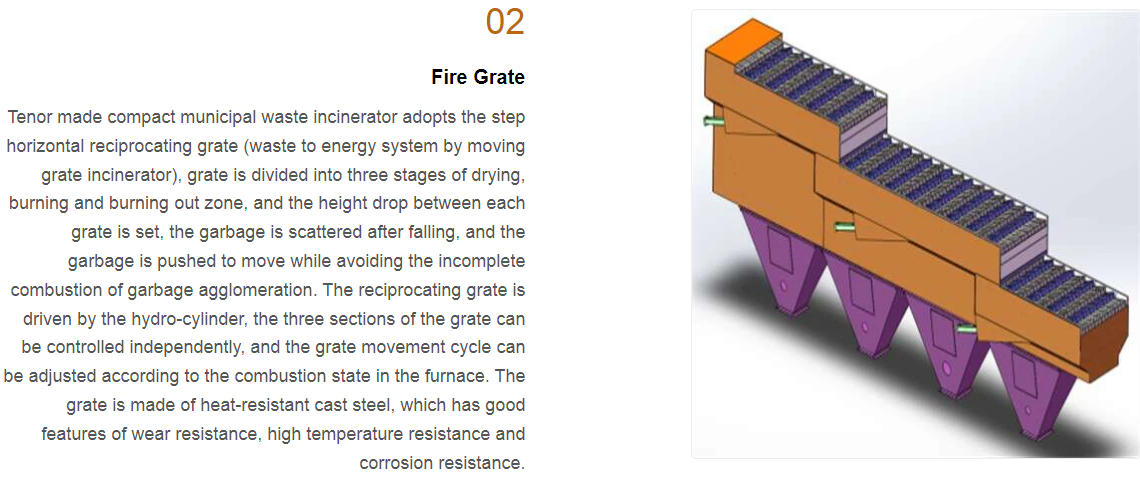

Grate advantages:

High efficiency stable combustion:

The garbage is fully burned, the thermal ignition reduction rate is low,Equipment performance: The grate has good wear resistance, high temperature resistance and corrosion resistance, low damage rate, low replacement frequency and low maintenance cost.The pores and gaps are matched with air inlet, and the overall air inlet effect is more uniform, which is conducive to uniform combustion and stable combustion.

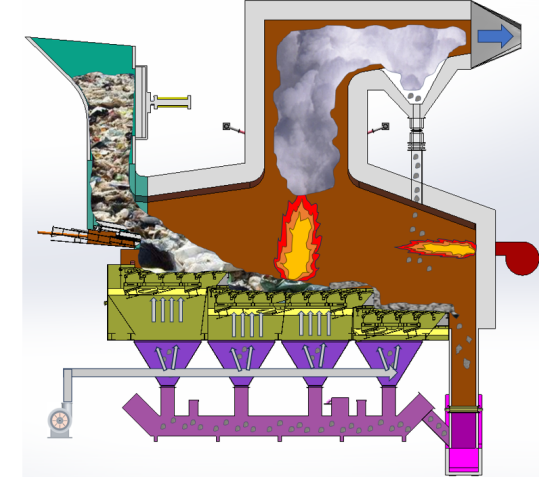

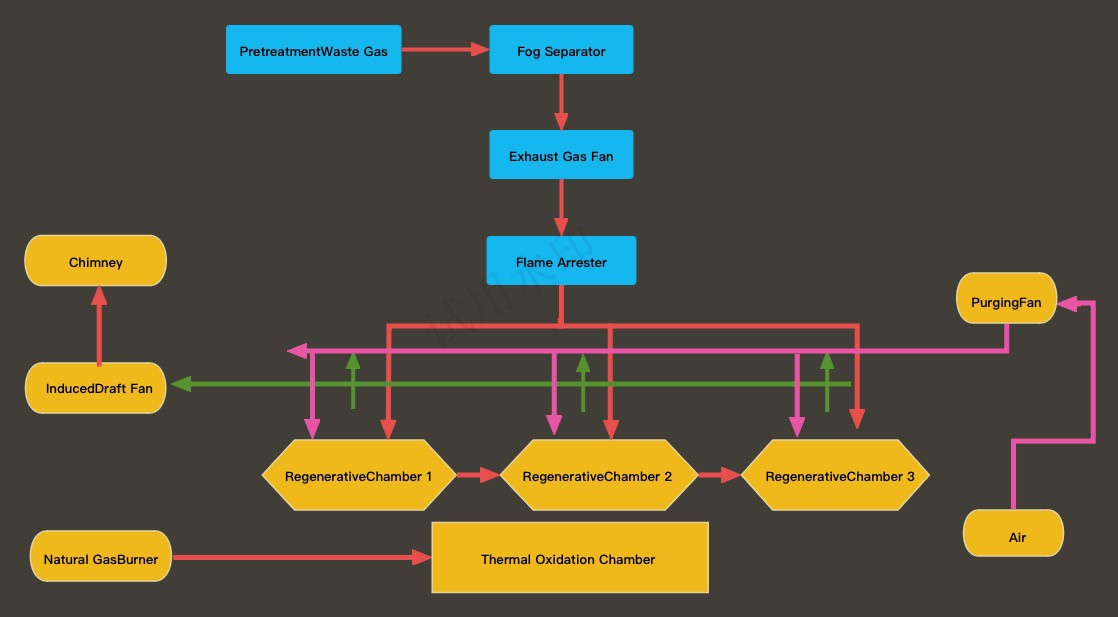

Solid waste incinerator process flow

Following the garbage in the furnace, the three sections: burning, drying and burning out are carried out with certain temperature and pressure. Following the trash into the furnace, the three sections are: burning, drying and burning off, under a pressure and temperature.

The ash from the combustion of garbage is pumped into the wet-slagging machine via the slagging bucket, and the remainder goes to the slag pit. The horizontal conveyor for ash leakage is attached under the air-chamber, and small amounts of slag and ash under the grates are then sent to the machine that removes wet slag.

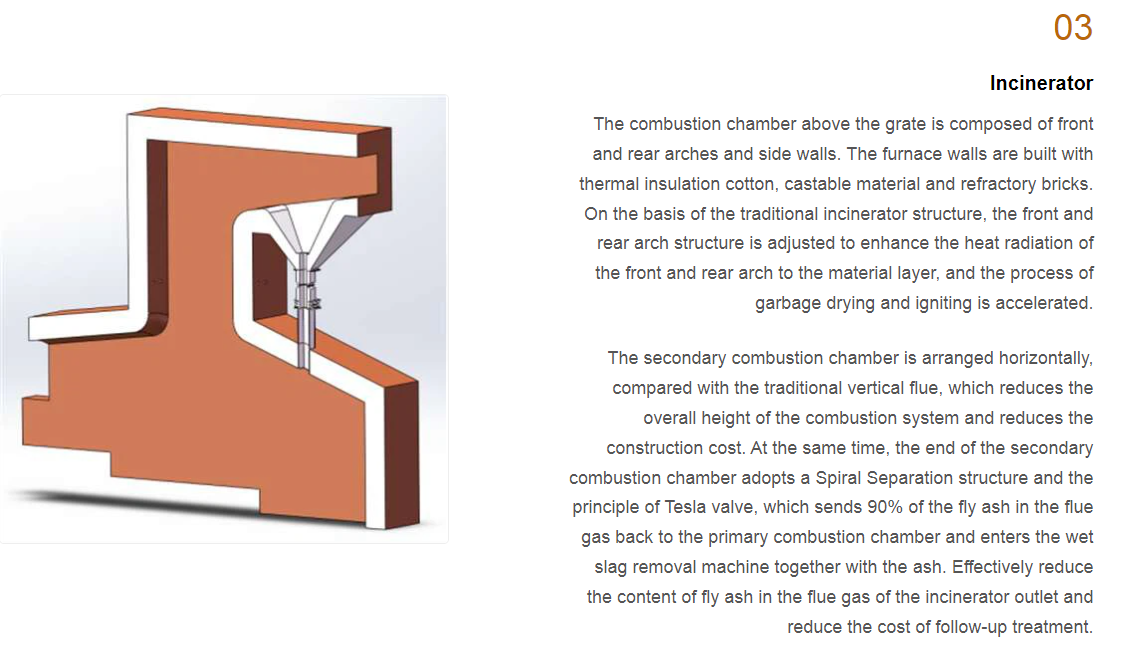

The combustion flue gas enters through the throat into the second combustion chamber. Secondary air is then added in the throat for the purpose of adjusting the furnace's temperature, ensuring complete combustion, and controlling the production of nitrogen dioxides.

It is possible to choose between hot water, steam, or electricity production according to project size and cost benefits. Deacidification of the flue gas is done after it has been cooled by heat transfer.

Process charateristics

- Simple structure ,easy installation and operation;

- All equipment automation; Reduce the working load of the furnace personnel;

- Low total building height and low construction cost;

- The secondary combustion chamber adopts spiral dust removal structure and Tesla valve to reduce the fly ash content in the flue gas, reduce the subsequent dust removal cost, and extend the service life of the equipment.

- The waste combustion is sufficient, and the heat burn reduction rate is less than 5%;

- Pollutant emissions meet standards.

- Customized complete proposal and turn-key WTE equipment.

Waste to energy project display

garbage incinerator 50 tons/d

Benefite of Waste Management

MSW incinerator can produce steam, hot water and electricity generation, sustainable Power from Small-Scale Waste Incineration.

Application:Township, cities and towns, government, power plant.

Delivery Process

Construction

Discharge hall entrance

Garbage pit and grab buc

Ash

Sludge dryer

Chimney

On-line monitoring of flue gas

Equipment control system

Equipment monitoring system

Incineration process

FAQ

Q: How does an industrial trash incinerator work?

Q: What are the benefits of an industrial trash incinerator?

Q: Are there any drawbacks to using an industrial trash incinerator?

Q: What types of waste can be disposed of in an industrial trash incinerator?

Q: How do industrial trash incinerators address air pollution concerns?

Q: What is the role of public engagement in industrial trash incineration?