Incinerator

Product Technical Parameters

|

CAPACITY |

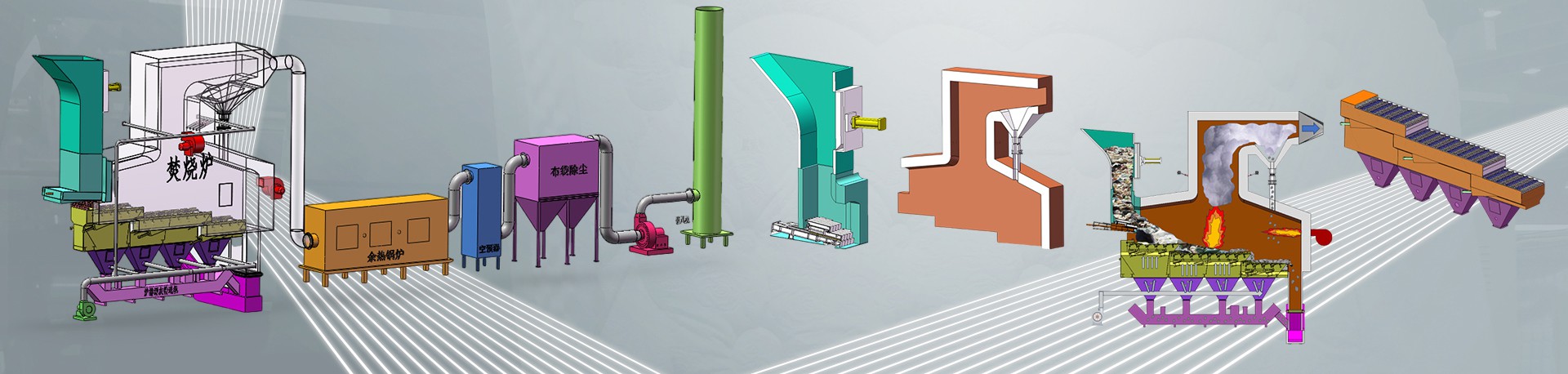

Technological Process |

Basic Parameter |

Scope of Application |

|

50t/d |

①Garbage into the furnace → incineration → cooling → flue gas treatment → standard discharge ② Garbage into the furnace → incineration → waste heat boiler → flue gas treatment → standard discharge |

Daily processing capacity: 50t Saturated steam capacity: 3~5t/h |

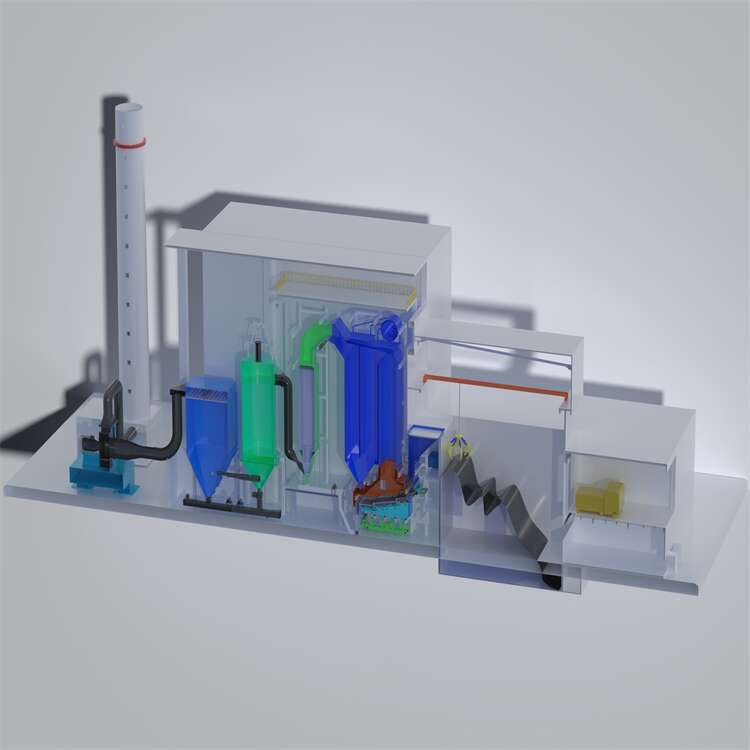

The project with a daily processing capacity of 50t is suitable for harmless and reduced treatment of domestic waste in small areas of villages and towns. Depending on the project situation, the high-temperature flue gas can be directly cooled and purified before being discharged, or a 3~5t/h saturated steam boiler can be used to produce and sell steam. It is not suitable for power generation. The project is small in scale. Under the premise of meeting the same environmental protection standards, the input per ton of garbage is too high, and the project has no profit point and is not economically feasible. It is suitable for non-profit demonstration projects or reliable steam users to increase a certain output value. The incinerator and the waste heat boiler in this scheme are arranged horizontally separately and connected by high-temperature flues. Compared with traditional large-scale waste incineration projects, the overall height of the equipment in this scheme is significantly reduced, and the total equipment height is below 20m. |

|

100~200t/d |

Waste into the furnace → incineration → waste heat boiler → flue gas treatment → standard discharge |

Daily processing capacity: 100~200t Saturated steam capacity: 8~20t/h |

The project with a daily processing capacity of 100t is suitable for harmless, resource-based and reduced treatment of domestic waste in small areas of villages and towns, and waste heat recovery and utilization. It is equipped with 8~10t/h saturated steam boilers. The scale is too small and unstable, and it is not suitable for power generation. However, the steam output is considerable, and it needs to be sold for profit or used in combination with other industries that need steam. The incinerator and waste heat boiler are arranged separately and horizontally. |

|

200~300t/d |

Waste into the furnace → incineration → waste heat boiler → flue gas treatment → standard discharge, steam used for power generation |

Daily processing capacity: 200~300t Superheated steam capacity: 16~30t/h Annual power generation: 32~48 million kwh |

The project with a daily processing capacity of 200~300t is suitable for harmless treatment of domestic waste in counties and waste heat recovery, and is equipped with a 20~30t/h superheated steam boiler + 4~6MW steam generator set. |

waste incineration systems Suppliers

Focusing on the application of technologies such as furnace arches, modular assembly, and dust reduction and dioxin removal inside the furnace to ensure full combustion of waste.

one-stop solution

professional team

high quality

what is waste incineration system?

Waste incineration systems are designed to burn non-hazardous municipal solid wastes (MSW) such as yard waste and household waste. It involves exposing the waste material to temperatures between 800°C and 1,200°C to convert the organic matter into heat, ash and gases.

Heat generated during the incineration can be used for district heating or to produce electricity. Before being released in the air, gases generated during the incineration process are treated and cleaned to reduce pollution and emissions.

These systems may include a variety of technologies such as fluidized-bed combustors and rotary ovens. They are usually integrated with waste to energy plants that convert thermal energy generated by the incineration into power.

Waste incineration can reduce waste to landfills, recover energy and help save the environment. However, it also has potential negative environmental effects and requires careful management of emissions.

- Simple structure ,easy installation and operation;

- All equipment automation; Reduce the working load of the furnace personnel;

- Low total building height and low construction cost;

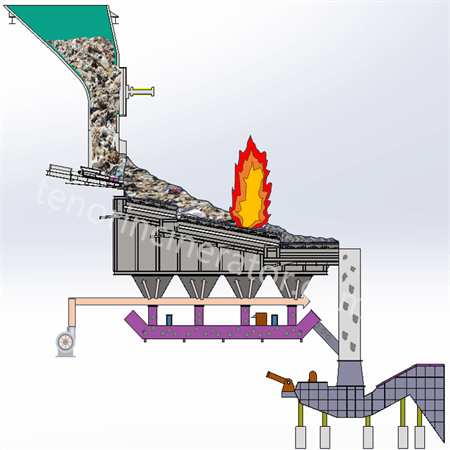

- The secondary combustion chamber adopts spiral dust removal structure and Tesla valve to reduce the fly ash content in the flue gas, reduce the subsequent dust removal cost, and extend the service life of the equipment.

- The waste combustion is sufficient, and the heat burn reduction rate is less than 5%;

- Pollutant emissions meet standards.

- Customized complete proposal and turn-key WTE equipment.

Process description of the waste incineration system

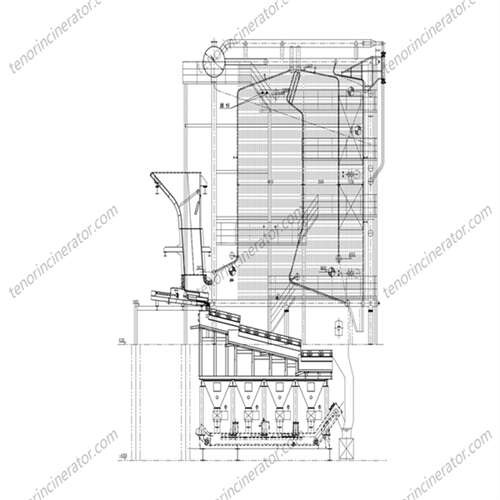

Tenor waste incineration grate is developed by Tenor Low Carbon New Energy Technology (Liaoning) Co., Ltd. The incineration system consists of feeder, grate, ash hopper, ash conveyor and slag remover, and it is suitable for the domestic waste incineration projects with a daily capacity of 30~600 tons.

why choose us?

We have Rich experience of manufacturing MSW incinerators, Compact incinerator, boiler grate stokers. mould design+welding+machining+precision castings

We have Five workshops and three casting plant, advanced - equipped TWO DENMARK DISA CASTING LINES

18

years

We have been working in the industry since 2006

100+

people

We have 100 workers, 2 people in the design department and 5 people in the sales department.

3

factory

It has 3 processing factory areas with an area of nearly 10,000 square meters.

Our Factory

Waste incinerators are used in many fields, especially in the waste treatment industry. The following are the main application areas of waste incinerators:

Municipal domestic waste treatment: With the acceleration of urbanization, the amount of domestic waste continues to increase, and garbage incinerators have become an effective means of processing these wastes. It reduces waste volume while recovering energy from the heat generated during the incineration process.

Industrial Waste Disposal: Waste generated from certain industrial processes can also be disposed of through incinerators, particularly those that are not suitable for landfill or other disposal methods.

In addition, garbage incinerators can also be used to process special waste, such as medical waste, hazardous waste, etc. High-temperature incineration can effectively eliminate harmful substances and reduce the impact on the environment.

In general, the application of waste incinerators helps solve waste disposal problems and also provides the possibility of energy recovery. However, the incineration process requires strict environmental protection controls to ensure that emissions comply with environmental standards and reduce the impact on the environment and human health.

Our Service Processes

Pre-sales Consultancy

1

>>

Confirmation of order

2

>>

Production

3

>>

Multi-Channel Shipping

4

>>

Confirmation of recei

5

>>

After-sale Services

6

Turning trash into treasure, sustainable energy from small-scale incineration.

Our address

No.2 Honggang Road, Ganjingzi District, Dalian City, Liaoning, China.

Phone Number

+86-15382281005

E-mail: sales@gyxh.net

As one of the most professional incinerator suppliers in China, we're featured by quality products and good service. Please rest assured to buy high-grade incinerator made in China here from our factory.

industrial waste incinerator manufacture, industrial solid waste incinerator, incinerator waste treatment machinery