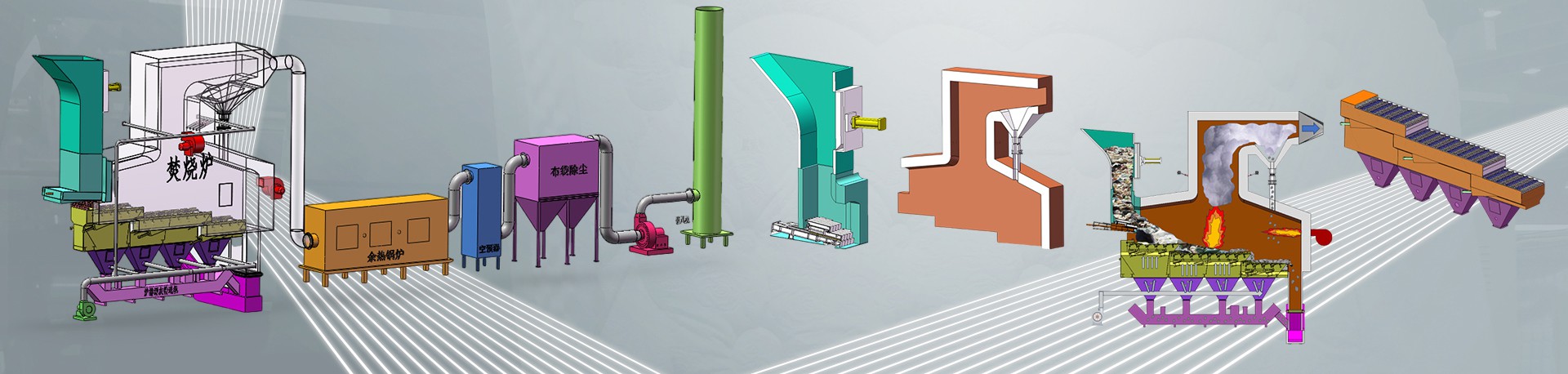

Waste Furnace

An incinerator is a furnace for burning waste. Modern incinerators include pollution mitigation equipment such as flue gas cleaning. There are various types of incinerator plant design: moving grate, fixed grate, rotary-kiln, and fluidised bed.

Benefits of Waste Furnace

Enhanced Performance

Regular maintenance ensures that all components of the incinerator are functioning properly, optimizing fuel efficiency, combustion efficiency, and overall waste disposal effectiveness.

Extended Lifespan

Proper maintenance extends the lifespan of the incinerator, preventing costly breakdowns and premature replacements.

Reduced Emissions

Regular servicing minimizes harmful emissions, ensuring adherence to environmental regulations and protecting air quality.

Improved Safety

Proper maintenance identifies and addresses potential safety hazards, preventing accidents and minimizing the risk of fire or explosions.

Compliance with Regulations

Regular servicing ensures that the incinerator meets and maintains compliance with local, national, and international environmental regulations.

Why Choose Us

Advanced equipment

We take strong measures to ensure that we use the highest quality equipment in the industry and that our equipment is regularly and meticulously maintained.

Rich experience

Has a long-standing reputation in the industry, which makes it stand out from its competitors. With over many years of experience, they have developed the skills necessary to meet their clients' needs.

Efficient and convenient

The company has established marketing networks around the world to provide high-quality services to customers in an efficient and convenient manner.

Quality assurance

In terms of quality assurance, the company strictly follows the standards and norms of the industry quality system. Adopt industry-leading testing equipment to ensure product quality and good reputation.

Professional team

We have a team of skilled and experienced professionals who are well-versed in the latest technology and industry standards. Our team is dedicated to ensuring that our customers get the best service and support possible.

Competitive prices

We offer our products at competitive prices, making them affordable for our customers. We believe that high-quality products should not come at a premium, and we strive to make our products accessible to all.

Industrial Waste Incinerator Market Size And Scope

The Industrial Waste Incinerator Market is poised for substantial growth in the coming years, driven by several key strategies and factors. Market players are increasingly focusing on product innovation and development to meet evolving consumer demands and preferences. Expansion into emerging markets and strategic partnerships or collaborations are also pivotal strategies for market growth. Additionally, investments in research and development to enhance technological advancements and improve product quality play a vital role. Moreover, the market's future scope looks promising due to the rising adoption of digitalization and the integration of advanced technologies, which are anticipated to open new avenues for growth and innovation.

Parts of an Incinerator

Primary Chamber

This is where the waste is loaded and ignited. In most incinerators, ignition is due to high ambient temperatures being retained in the chamber lining.

Secondary Chamber

Secondary chambers are required by law in Europe, the United States, Australia and Canada to prevent the formation of harmful particles. In many countries, the law states that the flue gases must remain in the secondary chamber for at least 2 seconds at a temperature of 850°C or more.

Velocity Hood

Most incinerators require a chimney height of at least 3 meters. In densely built-up areas or where atmospheric conditions require, the chimney height will be higher. This design pushes the gases high into the air so that they can be widely dispersed.

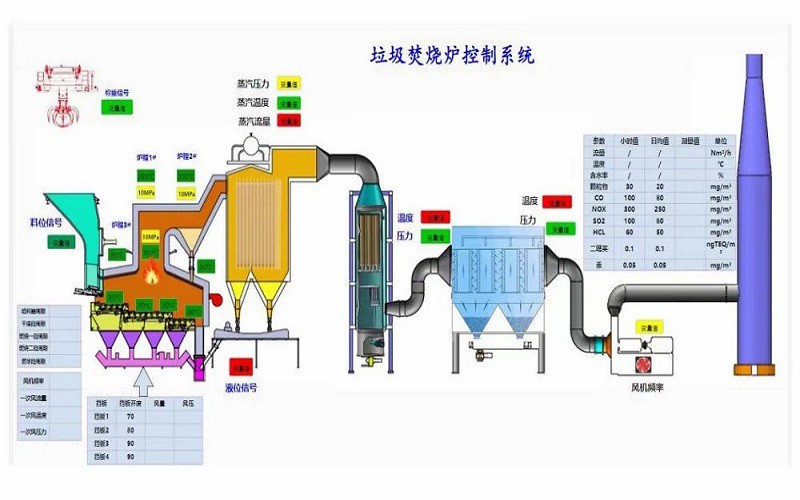

Control Panel and Thermocouples

These control the operation of the machine and ensure that the combustion chamber reaches the required temperature before any waste is loaded for incineration. The settings can be fully customized to the operator's requirements, depending on the type of waste.

Burner

The burner is used to heat the incinerator and is usually turned off during the combustion phase.

Fuel Tank

This is where the fuel is stored. The burner will vent directly into the fuel tank when the incinerator is in use.

How to Choose a Waste Incinerator

Determine the type of garbage incinerator. According to the composition, processing volume, processing requirements and environmental protection requirements of the garbage, choose the appropriate type of garbage incinerator. Common types of garbage incinerators include mechanical grate incinerators, fluidized bed incinerators, rotary kiln incinerators, etc. Different types of incinerators are suitable for different types of garbage, and their treatment effects and characteristics are also different.

Choose the appropriate processing volume According to the processing volume of garbage, choose a suitable garbage incinerator. If the garbage processing volume is large, you need to choose an incinerator with a stronger processing capacity; conversely, if the garbage processing volume is small, you can choose an incinerator with a smaller processing capacity.

Consider environmental protection performance The environmental protection performance of the garbage incinerator is one of the important factors in selection. A garbage incinerator that meets environmental protection standards, has low nitrogen oxide emissions, low smoke emissions, and low noise should be selected. At the same time, it is also necessary to consider its ability to handle odors and whether it is necessary to add combustion aids.

Examine the reliability of the equipment The garbage incinerator is a continuously operating equipment, and its reliability is crucial for garbage treatment. When choosing a waste incinerator, factors such as the life of its key components, maintenance, and safety protection should be considered to ensure its long-term stable operation.

Consider the energy consumption and operating cost of the equipment The operating cost of the waste incinerator includes energy consumption, maintenance costs, and labor costs. When choosing a waste incinerator, its energy consumption and operating costs should be considered, and an economic analysis should be conducted. At the same time, it is also necessary to consider its demand for fuel and whether other auxiliary fuels need to be added.

Examine the degree of automation of the equipment With the development of technology, automation technology has been widely used in the control and monitoring of waste incinerators. When choosing a waste incinerator, its degree of automation should be considered, including automation control, monitoring systems, etc. Equipment with a high degree of automation can reduce labor costs, improve processing efficiency, and reduce the impact of human factors on the processing effect.

Consider the maintainability and after-sales service of the equipment The waste incinerator is a large-scale equipment that requires regular maintenance and maintenance. When choosing a waste incinerator, its maintainability should be considered, including factors such as the structure of the equipment and the replacement of wearing parts. At the same time, the quality and response time of after-sales service also need to be considered to ensure that the equipment is maintained and maintained in a timely manner during operation.

Fundamental Principles of Incinerator Design

Waste management has become a major global concern, and incineration is now increasingly used to treat waste that cannot be economically recycled. The combustion of conventional well-specified fossil fuels is a very complex process, as it involves two-phase turbulent reacting flows including radiative heat transfer. Incineration is even more complex because the waste is poorly specified and its composition changes from moment to moment. In the past, the design of incinerators was not based on a fundamental understanding and modeling of the process, but had to use empirical rules.

In the past few years, computational fluid dynamics (CFD) has provided a way to model the freeboard region in conventional municipal solid waste incinerators, but no rigorous first-principle-based model of the bed region is available in the open literature. Predicting the composition of the flow emerging from this region is particularly important, as it provides the "upstream" boundary condition for the flow calculations in the freeboard. For example, calculating the subsequent history of heavy metals requires knowledge of their emission rates from the combustion bed.

Processes within the bed include drying, pyrolysis, oxidative combustion, and char gasification. In addition, the movement of the grate is intended to mix the waste as it is burned. Indeed, the existence of a rigorous bed model would also allow for the optimization of the grate design and, if there is immediate data on the feed, the design of a reasonable combustion control strategy. This paper presents a preliminary model of in-bed combustion based on the governing equations for the combustion of wastes in various "zones" in the upward airflow, their movement, and radiative heat transfer within the bed. Gas emissions from the bed surface are very non-uniform, with oxygen emitting from the ends of the bed, organic compounds from a third of the zone, and carbon monoxide from the center. The surface layer in the center portion of the bed consists of char, and gases rise from the underlying oxide layer, containing NOx from the fuel nitrogen. The char zone thus acts as an important reburning zone, and it is argued that this reduces some of the NOx to nitrogen. This is important because minimizing NOx by optimizing the basic combustion process may be more environmentally friendly than subsequently controlling NOx by injecting reactants such as ammonia.

Using CFD to calculate flows and combustion within the freeboard can quantify the consequences of design concepts, but guidelines are needed to design specific design concepts that are worth investigating. Thus, computers cannot "invent" designs, but they can quantify the consequences of ideas.

Incinerator design requires a rational combination of basic combustion science, clever engineering guided by an understanding of mixing processes, and, last but not least, practical experience from previous failures and successes.

Operating Procedure of Incinerator

The primary combustion chamber of the incinerator is intended for burning solid waste or sludge oil, while the secondary combustion chamber is intended for burning off any unburned exhaust fumes. A primary burner is installed in the primary combustion chamber, which receives diesel oil to ignite it initially. After that, the primary burner receives the sludge oil until it ignites.

The primary burner is then turned off manually or automatically.

For effective combustion, the sludge burner receives atomizing air.

To control the amount of sludge entering the conversion space, a pressure-regulating valve is supplied on the sludge return line.

The primary burner' s heat will cause the solid waste to dry out and begin burning, as well as ignite the sludge oil.

The primary combustion chamber' s enormous transmission area optimizes the solid waste' s drying and burning.

The primary combustion chamber' s gases will burn out in the secondary combustion chamber. The primary and secondary combustion chambers are separated by a wall of ceramic heavy-duty refractory liners.

Solid waste is fed into the incinerator through the feeding door when it is solid garbage or waste.

The primary burner cannot be lit if this door is open, but the rest of the combustion process continues as usual.

Applications of Incinerator

Medical waste

Medical wastes generated from laboratories, hospitals, and health clinics can pose health risks if not properly treated or disposed of. Incinerators are designed to destroy and neutralize medical waste.

Animal waste

Incinerators are employed to dispose of animal wastes, including carcasses, waste, and byproducts, thereby preventing the spread of infection and viruses.

General waste

General wastes include less harmful wastes from sites such as mining, small communities, and military operations, which must be destroyed to reduce environmental impact. Thus, incinerators are devised to incinerate such wastes.

Nanomaterial wastes

Incinerators are utilized to dispose of nanomaterial wastes such as consumer products in municipal solid waste, wastes from nanotechnology research and development, hazardous wastes, etc.

High-efficiency combustion technology

High-efficiency combustion technology is one of the important directions of technological innovation of garbage incinerators. By improving the design of the combustion chamber, optimizing the air supply and fuel mixing, and adopting advanced combustion control systems, the combustion efficiency of garbage incinerators has been significantly improved. This not only reduces energy waste, but also improves the stability and reliability of garbage incineration.

Low nitrogen oxide combustion technology

In response to the problem of nitrogen oxide emissions generated during garbage incineration, researchers have developed low nitrogen oxide combustion technology. Through selective catalytic reduction (SCR) technology or selective non-catalytic reduction (SNCR) technology and other means, the generation and emission of nitrogen oxides are effectively reduced, reducing pollution to the atmosphere.

Flue gas treatment technology

The innovation of flue gas treatment technology is also an important manifestation of the technological progress of garbage incinerators. The use of activated carbon adsorption, wet dust collector, bag dust collector and other technologies to purify the flue gas can effectively remove harmful substances in the flue gas, such as sulfur dioxide, particulate matter, etc., to ensure that the flue gas emissions meet environmental protection standards.

Ash resource utilization technology

As the concept of resource utilization has become more popular, ash resource utilization technology has also received widespread attention. By converting the ash produced by garbage incineration into valuable resources, such as building materials, landfill cover materials, roadbed materials, etc., it not only reduces the potential harm of ash to the environment, but also realizes the recycling of resources.

Intelligent technology

The application of intelligent technology has brought revolutionary changes to the operation and management of garbage incinerators. By introducing advanced technologies such as the Internet of Things, big data, and artificial intelligence, garbage incinerators have achieved intelligent control and optimized management. The intelligent control system can monitor the composition, water content, calorific value and other parameters of garbage in real time, automatically adjust the combustion conditions, and ensure the stability and economy of garbage incineration. At the same time, intelligent fault diagnosis technology can provide early warning and diagnosis of equipment failures, reducing the maintenance cost and downtime of equipment.

New incineration technology

In recent years, new incineration technologies such as low-temperature magnetization degradation furnaces have also been gradually applied. This technology reduces the emission of harmful gases and pollutants by reducing the participation of oxygen. At the same time, its high efficiency, energy saving, and environmental protection make it a scientific and technological innovation in the field of garbage treatment.

Our Factory

Tenor Low Carbon new Energy Technology (Liaoning) Co., Ltd. was established in 2021 and registered at the Industrial Incubation Base of Dalian University of Technology. Through cooperation with thermal power departments, environmental departments, mechanical departments, inorganic materials and other disciplines of HIT and Dalian University of Technology, the company focuses on designing and developing complete sets of small urban waste incineration technologies; Focusing on the application of technologies such as furnace arches, modular assembly, and dust reduction and dioxin removal inside the furnace to ensure full combustion of waste.

FAQ

As one of the most professional waste furnace suppliers in China, we're featured by quality products and good service. Please rest assured to buy high-grade waste furnace made in China here from our factory.

bte waste incinerator, municipal waste incinerator, incineration garbage disposal