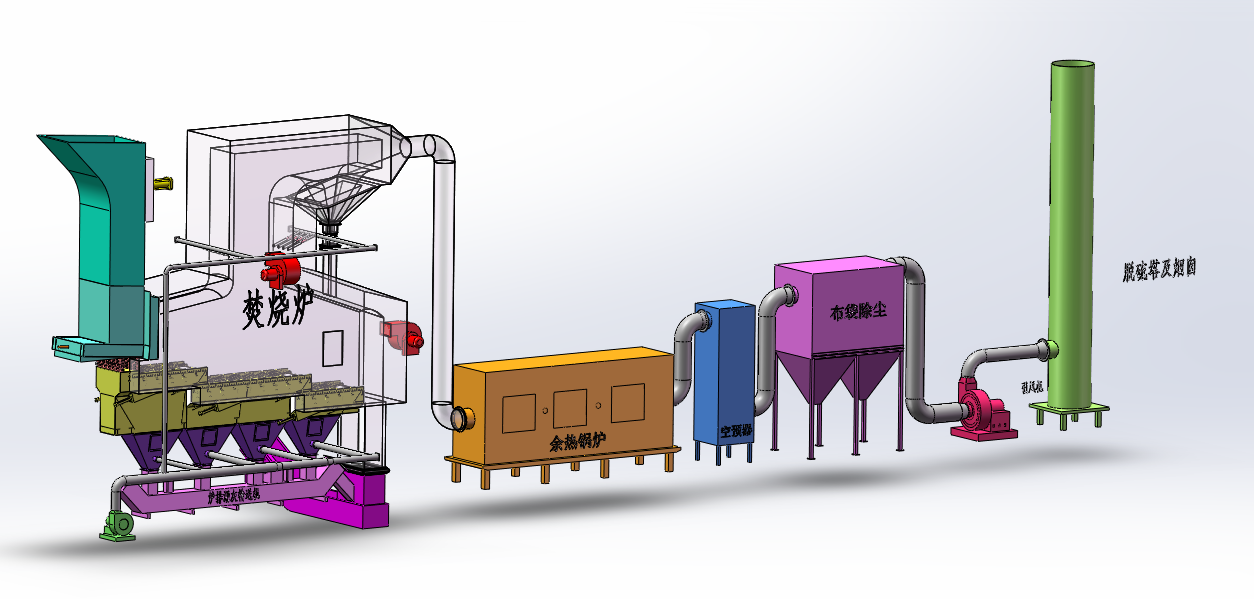

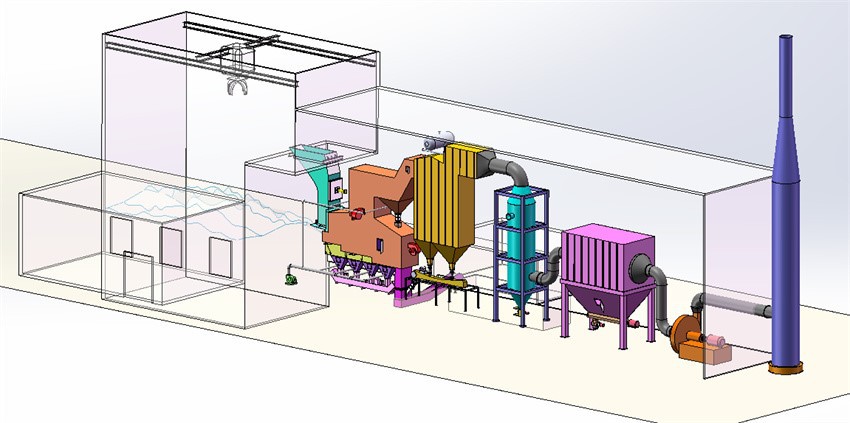

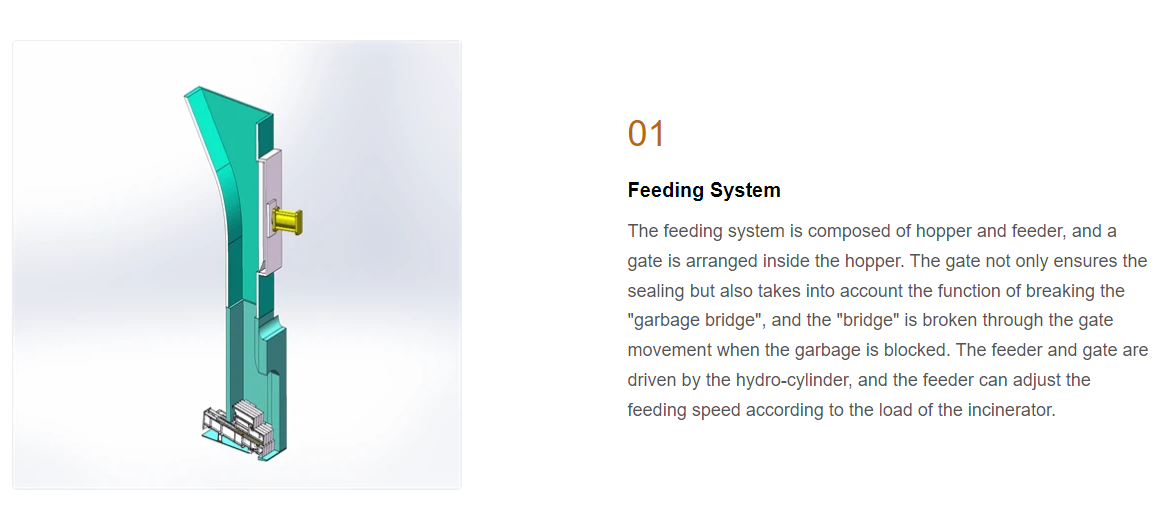

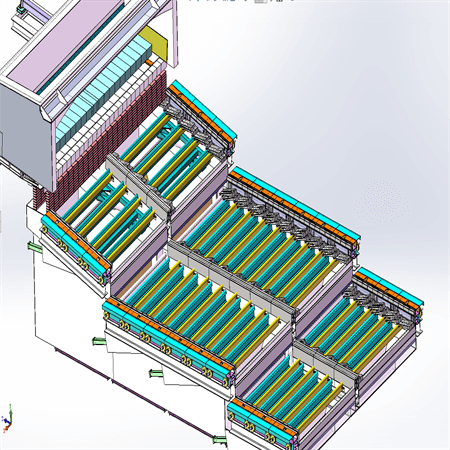

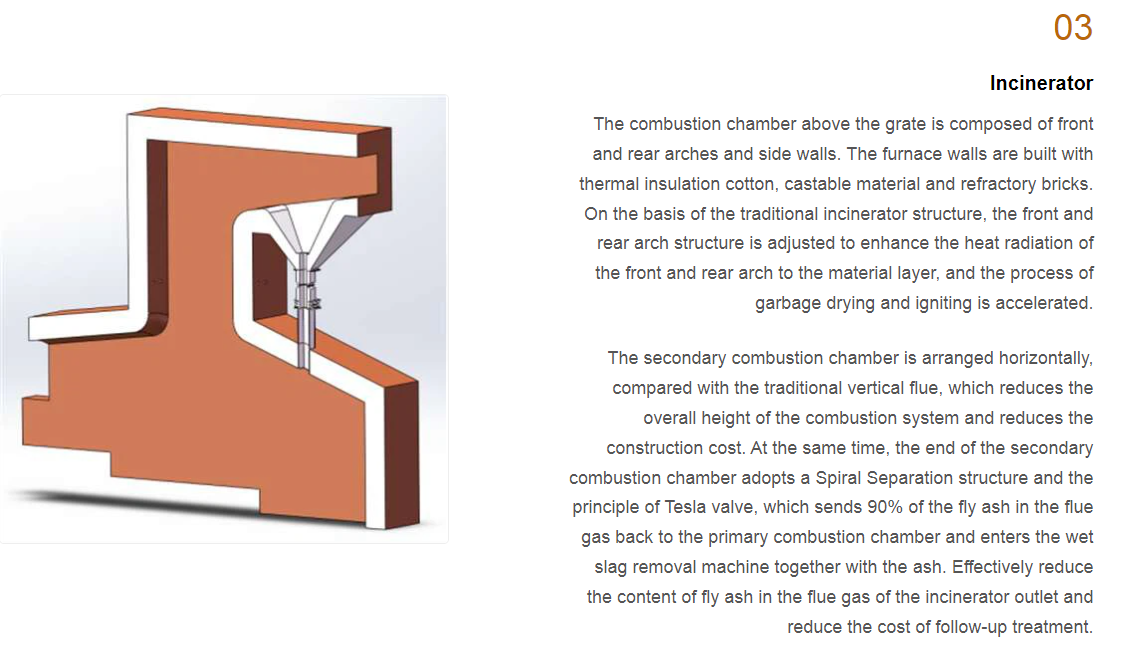

Tenor Low Carbon New Energy Technology Co., Ltd. developed a small waste incineration systems with the research team at Dalian University of Technology. WTE incineration systems include a hopper and feeding machine as well as stoker, step grates, ash hoppers, slag removal systems, transport aircraft, combustion chambers, and slag hoppers.

active members

years experience

production plants

Pre-sales and after-sales departments

Core strengths

Choose the plan that suits you best.

Production and processing capabilities

We have five workshops and three foundries, one-stop solution for mold design + welding + machining + precision castings.

Customization and design capabilities

Professional team, quality service

18 Years of Deep Technology Accumulation

It has 18 years of rich experience in manufacturing waste incinerators, compact incinerators, and boiler grate stokers.

Advanced equipment

Owns two Danish DISA casting lines

Tenor made small waste incineration system was developed by Tenor Low Carbon New Energy Technology (Liaoning) Co., Ltd. and Dalian University of Technology research team. WTE incineration system including hopper, feeding machine, stoker furnace,step grate, ash hopper, slag removal system, transport aircraft and combustion chamber, suitable for daily capacity of 50 to 250 tons/d of small domestic waste incineration projects.

Basic feature

|

Product parameters

|

Scale(t/d) |

Number of furnaces |

Overall height of equipment(m) |

Floor space(m2) |

Emission standard |

|

50 |

1 |

17 |

60 |

《Pollution control standards for household waste incineration》(GB18485-2014) |

|

100 |

1 |

17 |

75 |

|

|

150 |

2 |

17 |

90 |

|

|

200 |

2 |

17 |

105 |

|

|

250 |

3 |

17 |

120 |

Main equipment

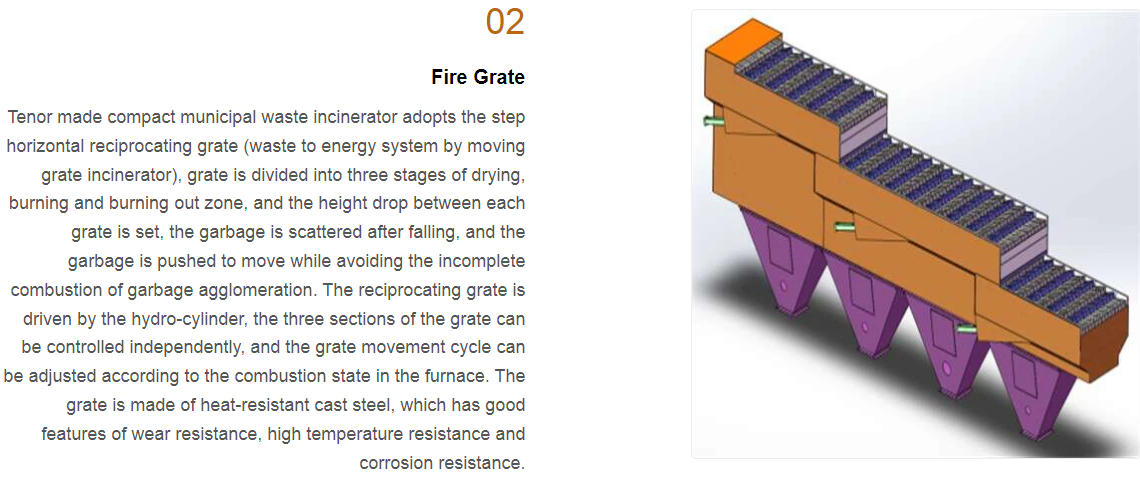

Grate advantages:

High efficiency stable combustion:

The garbage is fully burned, the thermal ignition reduction rate is low,Equipment performance: The grate has good wear resistance, high temperature resistance and corrosion resistance, low damage rate, low replacement frequency and low maintenance cost.The pores and gaps are matched with air inlet, and the overall air inlet effect is more uniform, which is conducive to uniform combustion and stable combustion.

Project case display

Construction

Discharge hall entrance

Garbage pit and grab bucket

Ash

Sludge dryer

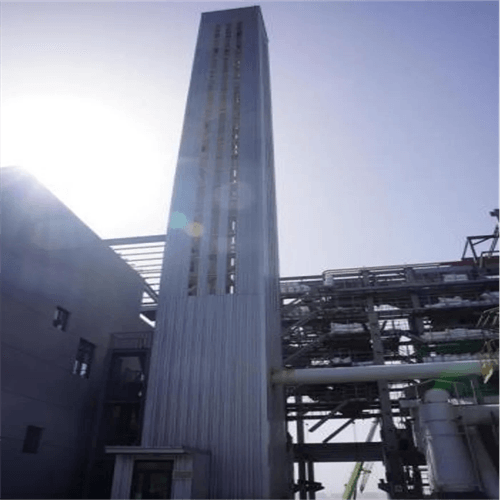

Chimney

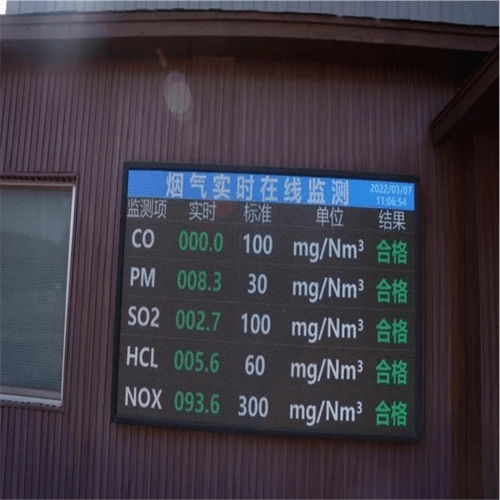

On-line monitoring of flue gas

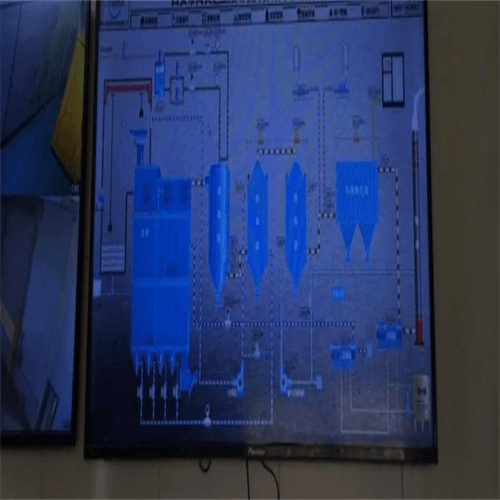

Equipment control system

Equipment monitoring system

types of CNC machining

Some main features of wet waste incinerators:

1. Feedstock flexibility: They can process a variety of wet waste streams, including food waste, the organic fraction of municipal solid waste and sewage sludge.

2. Design features: Wet incinerators are equipped with special grates or other mechanisms that are conducive to the combustion of wet materials. These systems promote efficient combustion by exposing the waste to high temperatures and ensuring an adequate supply of oxygen for complete combustion.

3. Thermal efficiency: Since additional heat is required to evaporate water, the incineration of wet waste requires more energy. Advanced designs use heat recovery systems to increase thermal efficiency, often combined with electricity generation or to provide heat for district heating systems.

4. Emission control: Wet waste incinerators must have strict emission control systems to comply with environmental regulations. These may include scrubbers, electrostatic precipitators, fabric filters and selective non-catalytic reduction (SNCR) systems to reduce pollutants such as dioxins, furans, particulate matter, sulfur dioxide and nitrogen oxides.

5. Moisture content: High moisture content in waste requires special considerations to prevent corrosion and maintain the structural integrity of the facility.

6. Process technology: Some wet waste incineration plants use advanced technologies such as fluidized bed combustion or rotary kilns to achieve better performance when processing wet raw materials.

7. Disposal of by-products: Ashes and other residues generated during incineration require further treatment or disposal in accordance with local environmental regulations.

8. Cost and Complexity: Wet waste incinerators generally involve higher capital and operating costs compared to dry waste incinerators, primarily due to the additional energy required to evaporate water and the complexity of the required emission control systems.

It is important to note that while wet waste incineration is an effective method of reducing waste volume and recovering energy, it is a complex process that requires careful planning, design, operation and maintenance to ensure environmental compliance and operational efficiency. As always, local regulations and the specific characteristics of the waste stream will significantly impact the design and operation of such a facility.

If you are interested in our products and services, you can download our PDF files directly, or contact us by email or Whatsapp!