Small-scale incinerators are a useful technology to combust household waste, medical waste, slaughter waste, etc. instead of discharging it in a landfill.

Benefits of Household Garbage Furnace

Reduce the volume of garbage

After incineration, the volume of domestic garbage is greatly reduced. This means that the use of landfills can be reduced and the service life of landfills can be extended. For cities, the space of landfills is very limited, so domestic garbage incinerators can effectively solve the problem of garbage disposal.

Energy recovery

The high temperature generated by burning garbage can be used to generate steam, which in turn drives the generator to generate electricity. This way of energy recovery can effectively utilize the organic matter in the garbage and reduce dependence on traditional energy. At the same time, the electricity generated by burning garbage can supply the city's electricity demand and reduce the demand for external power supply.

Reduce environmental pollution

Domestic garbage contains a large amount of harmful substances, such as heavy metals, organic solvents, etc. If these garbage are directly landfilled or piled up, it will cause groundwater and soil pollution. By burning garbage, harmful substances can be burned and pollution to the environment can be reduced. In addition, burning garbage can also reduce the release of odor and harmful gases in garbage and improve the surrounding air quality.

Harmless treatment

Burning garbage can completely burn organic matter and reduce the spread of germs and viruses in garbage. This is of great significance for preventing the spread of diseases. In addition, burning garbage can also convert organic matter in the garbage into ash, which can be used for soil improvement and improve soil fertility.

Strong controllability

The domestic waste incinerator has good control performance and can be adjusted according to the type and amount of garbage. This means that the incineration process can be flexibly controlled according to actual conditions to ensure complete combustion of garbage and reduce the possibility of secondary pollution.

Reduce greenhouse gas emissions

Incineration of garbage can reduce the emission of greenhouse gases such as methane. Compared with landfilling, the greenhouse gas emissions of incineration of garbage are lower. This is of great significance for mitigating climate change.

Why Choose Us

Advanced equipment

We take strong measures to ensure that we use the highest quality equipment in the industry and that our equipment is regularly and meticulously maintained.

Rich experience

Has a long-standing reputation in the industry, which makes it stand out from its competitors. With over many years of experience, they have developed the skills necessary to meet their clients' needs.

Efficient and convenient

The company has established marketing networks around the world to provide high-quality services to customers in an efficient and convenient manner.

Quality assurance

In terms of quality assurance, the company strictly follows the standards and norms of the industry quality system. Adopt industry-leading testing equipment to ensure product quality and good reputation.

Professional team

We have a team of skilled and experienced professionals who are well-versed in the latest technology and industry standards. Our team is dedicated to ensuring that our customers get the best service and support possible.

Competitive prices

We offer our products at competitive prices, making them affordable for our customers. We believe that high-quality products should not come at a premium, and we strive to make our products accessible to all.

Introducing the latest in eco-friendly technology - the smokeless garbage burner! Say goodbye to noisy and polluting garbage incinerators and hello to a clean, efficient and safe solution. Our innovative design incorporates advanced air filtration and combustion technology that virtually eliminates smoke and harmful emissions, making it perfect for use in urban areas or even indoors.

Our waste treatment machinery is the solution you have been looking for to efficiently and effectively manage your waste. Designed with cutting-edge technology, our machines are specifically designed to reduce the environmental impact of waste disposal. Our products are designed to accommodate various types of waste, including industrial, organic, and hazardous.

What Kind of Electricity Will Waste Incineration Produce

Electricity generation at incinerators will soon become closer in carbon intensity to coal and gas than to wind and solar. This is because increasing the proportion of hard-to-recycle plastic waste sent to incinerators will increase the carbon impacts of incineration. Plastic is derived from crude oil and the carbon is released when burnt. So while the electricity grid should be decarbonising as a result of more renewable energy sources coming online, electricity produced at the incinerator will become a major climate issue.

Due to increasing quantities of waste sent to incineration, incinerators will emit more toxins and pollutants that harm local air quality. Incineration makes a more significant negative contribution to local air quality than landfill.

Sort

- The first step of preparing your waste for incineration should be to sort through the waste. Pick out any high-value recyclable items for resale. This could be large pieces of glass or metal that can be re-used elsewhere.

- Whilst looking for items of value, it is also important that you search for any dangerous items and remove them from the waste. An example of a dangerous material would be batteries. If a battery is left in the waste and placed into the incinerator, it could potentially explode causing damage to your machine and staff. The battery would also release harmful fumes into the atmosphere when burnt which can cause a serious risk to the environment and human health.

Shred

- Shredding the waste before incineration is an important part of preparation. Shredding is a technique used in the disposal process of paper waste, agricultural waste, household waste, and industrial waste.

- Shredding the material is essentially breaking the material down into smaller pieces. Reducing the size of the waste allows you to burn more waste in one batch which can save money on the running costs of an incinerator.

Dry

- An additional step when preparing your waste for incineration is drying. The drying process involves reducing the moisture content of the waste load to as low as possible. We would recommend 30% moisture content for the best efficiency.

- If a batch of waste has high moisture content it will take a longer amount of time to completely burn the waste as the heat will be used to evaporate the moisture first. Reducing the moisture content allows for a quicker burn time improving efficiency. Most MSW (Municipal Solid Waste) will need to be dried depending on how and where it has been stored.

Determine batch size

- It is important that you determine a batch size suitable for your incinerator. Work out the optimum batch size that you can burn for the lowest cost. Having a method like this in place can help you to save money on the running costs for your incinerator.

- You must not overfill your incinerator as this can cause the slow-burning of the waste. It can also cause damage to your incinerator if you continue to overfill it. Whilst it is important not to overfill your incinerator it is also just as important not to have batches of waste that are too small.

- We recommend saving your small batches of waste so they can be added into the incinerator with other waste. Operating your incinerator with a small amount of waste is a huge waste of energy and fuel. Using this method long-term would cost a large amount of money.

Pre-heat your incinerator

- Before loading your waste into the incinerator you must first pre-heat it. You must preheat your incinerator to a temperature of 850⁰C.

- Putting waste into an incinerator with a cooler temperature can cause a mix of harmful particles to form from the waste. These particles can cause serious harm to humans and the environment, so it is essential that you make sure your incinerator has been preheated to 850⁰C before loading in any of your waste. The reason that 850⁰C is given as temperature is that it is hot enough to kill any of these harmful air pollutants before they are released.

Load your incinerator

- Once you have completed all of your pre-preparation steps and your incinerator reaches 850⁰C, it is time to load your waste into the incinerator! Load your waste carefully into the incinerator ensuring you take all safety precautions. Make sure you' re wearing all necessary safety equipment to avoid the risk of being harmed in the loading process.

- Temperatures in our incinerators can reach up to 1100⁰C, so it is important that you follow all guidelines and safety regulations when you' re operating an incinerator.

Let it cool

- Once the combustion process is complete, it is important that you let the incinerator cool down as well as the ash. Temperatures inside of the incinerator are extremely hot so it is likely that the outside of the incinerator will be extremely hot too.

- It is important that the ash is also cool when it comes to de-ashing. Removing the ash when it is still hot can cause the ash to ignite and start a fire. To adhere to health and safety regulations, make sure that both the incinerator and ash are cool before handling.

De-ashing

Once your incinerator and ash have cooled to a reasonable temperature, you can easily de-ash the system ready for the next batch. Some of our incinerator models also have an auto de-ashing system which minimizes the contact the operator has with the incinerator. This removes the risk of any burns from high temperatures or irritation from fly ash.

Spot Check

Once your incinerator has been de-ashed and is completely cool, you should run a spot check on your incinerator. Places that you should check are burners, chamber, and fuel lines. By making sure everything is in working order, you can ensure good quality burns and help to prevent any problems in the future. This will save you time and money by preventing any issues from progressing.

Re-load

After you have spot-checked your incinerator to ensure everything is in working order, you are ready to repeat the steps all over again to re-load your next batch of waste!

What is Included in Incinerator Servicing

Burners and Thermocouples

Inspecting and testing burners and thermocouples ensures proper ignition and temperature control.

Rope Seals and Fibre Lining

Checking the integrity of rope seals and fibre lining prevents leaks and ensures efficient combustion.

Refractory Concrete Items

Inspecting refractory concrete items for cracks or damage maintains the incinerator's structural integrity.

Control Panel

Checking the control panel for proper operation ensures accurate monitoring and control of the incinerator.

Overall Inspection

A thorough inspection of the entire incinerator, both internally and externally, identifies any potential issues or areas requiring attention.

Burner Test

Conducting a comprehensive burner test ensures that the burner is functioning correctly and achieving the desired combustion temperature.

Replacement of Necessary Parts

Replacing worn or damaged parts with original equipment manufacturer (OEM) components maintains the incinerator's performance and safety.

Expert Advice

Experienced technicians provide expert advice on any potential issues and recommend necessary maintenance or repairs.

Common Incinerator Types

Mass Burn Incinerators

The predominant type is used for untreated mixed municipal solid waste. High volume throughput continuous units thermally size and mix waste on grates or tumbling kilns.

Modular & Batch Incinerators

Used for consistent but smaller waste streams like industrial hazardous waste or sewage sludge. Pre-calculated batches result in optimized burns.

Rotary Kiln Incinerators

A rotating cylindrical kiln that agitates and conveys waste through the combustion chamber to control residence times. Used for hazardous waste, medical waste, and sludge.

Fluidized Bed Incinerators

Injects air from below into a bed of sand and waste materials, allowing mixing and transfer of oxygen across all waste for an efficient, complete burn.

Gasification & Pyrolysis Systems

Decompose waste via external heat to produce syngas for energy use while concentrating & reducing solids and contamination. Limited waste applications due to technical complexity.

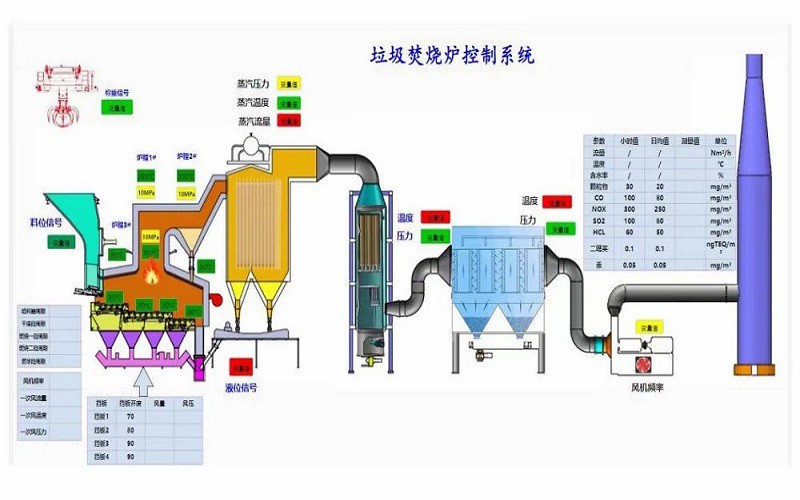

How Is the Energy Distribution of Domestic Waste Incinerators Completed

Transportation and storage of garbage

Domestic waste is first collected and transported to the waste incineration plant. Before entering the incinerator, the garbage needs to be stored and pre-treated. The storage link is mainly to balance the output of garbage and the processing capacity of the incinerator so that the garbage can enter the incinerator evenly. At the same time, the pretreatment link includes crushing, screening and sorting the garbage to remove large garbage, paper, plastic, glass and metal and other recyclables, reduce the amount of garbage entering the incinerator, and increase the calorific value of the garbage.

Combustion process

Domestic waste is burned in the incinerator to release heat. During the combustion process, the organic matter in the garbage reacts chemically with oxygen to generate carbon dioxide and water vapor, while releasing a large amount of heat. Part of this heat is used to maintain the temperature in the waste incinerator, and the other part is converted into steam or electricity through the waste heat recovery system.

Waste heat recovery

Waste heat recovery is an important part of the energy distribution of domestic waste incinerators. The heat generated during the combustion process is converted into steam or electricity through the waste heat recovery system. The recovered energy can be used for heating, power generation and other purposes to achieve energy recycling. Common waste heat recovery methods include waste heat boilers and gas turbine combined cycle power generation. Waste heat boilers can convert the heat in the high-temperature flue gas generated by combustion into steam for heating or driving steam turbines to generate electricity. The gas turbine combined cycle power generation directly sends the high-temperature flue gas into the gas turbine, mixes it with air and burns it to generate mechanical energy, and then converts it into electrical energy through the generator.

Flue gas treatment

During the combustion and waste heat recovery process, a large amount of flue gas will be generated. These flue gases contain a variety of harmful substances, such as sulfur oxides, nitrogen oxides, heavy metals, etc., which need to be purified before they can be discharged. The flue gas treatment system includes desulfurization, denitrification and dust removal, which can effectively remove harmful substances in the flue gas and reduce pollution to the environment. The treated flue gas is finally discharged into the atmosphere through the chimney.

Residue treatment

Some residues, including slag and fly ash, will be generated during the incineration of domestic waste. These residues need to be properly handled to avoid impacts on the environment and human health. Slag can be recycled after cooling, crushing and screening, such as making building materials. Fly ash needs to be solidified to stabilize the harmful substances in it, and then safely landfilled or recycled.

Primary chamber

All garbage will be fed into the primary chamber and burned for the first time there. The primary chamber is where the waste vapourises. The low air-to-fuel ratio in this starved-air chamber causes the waste to dry out and makes it easier for it to evaporate, burning up most of the carbon.

Secondary chamber

- Waste-derived volatile/gasified substances are transferred to the secondary chamber. To complete combustion, more air is injected in the second stage into the volatile gases created in the initial chamber. Temperatures in the secondary chamber are higher than those in the primary chamber. Due to the appropriate residence time, high temperature, and 100% surplus air in the secondary chamber, the gaseous products (volatile material) are oxidized. The gases are handled after they exit the secondary chamber.

- The gases are introduced to the droplet separator, where the moisture is taken out of the gases. This lowers the temperature of the flue gas, making it safe to release into the atmosphere.

Flue Stack

The term "chimney" also applies to the flue stack. Stack height requirements for most incinerators are 3 meters or greater. In more populated places or where the atmosphere requires it, this requirement will be greater.

Control panel and thermocouples

These regulate the machine's operation and guarantee that the chambers are heated up before any waste is loaded for incineration. Depending on the type of waste, the settings can be tailored to the operator's needs.

Burners

These are utilized to warm the incinerator up and are often turned off throughout the burning process.

Fuel tanks

The fuel is kept in storage. During the operation of the incinerator, the burners will have direct lines into the tank.

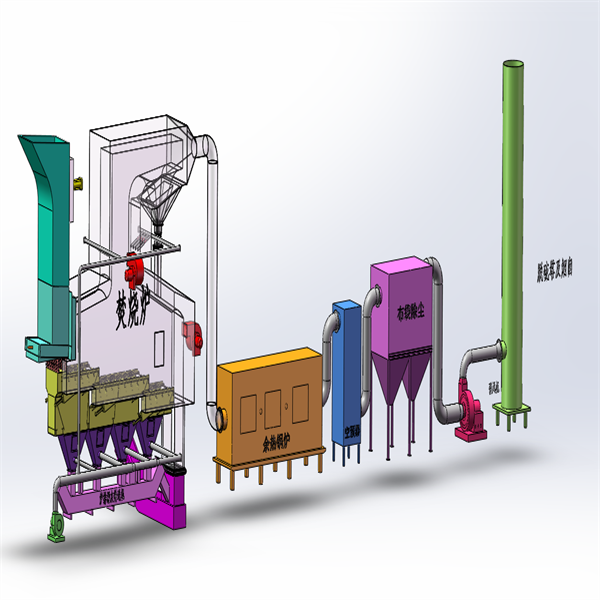

Our Factory

Tenor Low Carbon new Energy Technology (Liaoning) Co., Ltd. was established in 2021 and registered at the Industrial Incubation Base of Dalian University of Technology. Through cooperation with thermal power departments, environmental departments, mechanical departments, inorganic materials and other disciplines of HIT and Dalian University of Technology, the company focuses on designing and developing complete sets of small urban waste incineration technologies; Focusing on the application of technologies such as furnace arches, modular assembly, and dust reduction and dioxin removal inside the furnace to ensure full combustion of waste.