Reciprocating Step grate

in one-stop service

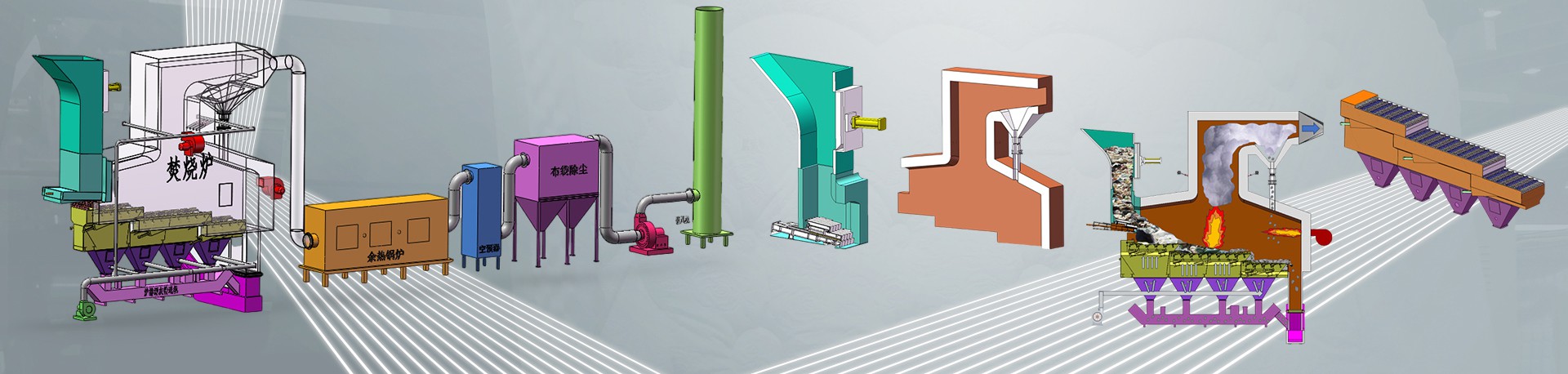

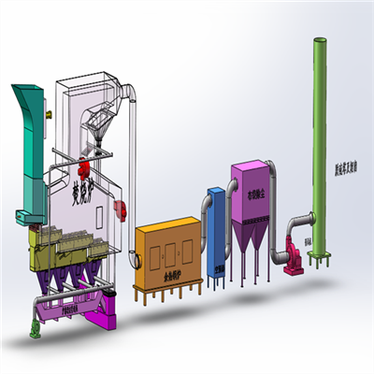

Tenor Low Carbon New Energy Technology (Liaoning) Co., Ltd. was founded in 2021, the company is located in Dalian City, Dalian University of Technology Industrial Incubation Park, the production base is located in Yantun, Paoai Village, Wafangdian City, Liaoning Province. Our company covers a total area of 500,000 square meters, more than two hundred employees, with fixed assets of 500 million yuan, more than 400 sets of major production equipment, machining, riveting and welding, casting, assembling and other production workshops, with two advanced The company has two advanced Disha casting production lines in Denmark, supporting automatic spheronization automatic equipment and spectral monitoring equipment, and the quality of products is at the leading level in China.

The company's main business includes the Design, Production, Technology development and Sales of complete sets of waste incineration treatment equipment, the company has long cooperated closely with Harbin Institute of Technology, Dalian University of Technology, Nanjing University of Science and Technology and other renowned universities, with reliable professional technical support, experienced design team, to provide customers with high-quality products.

Products Description

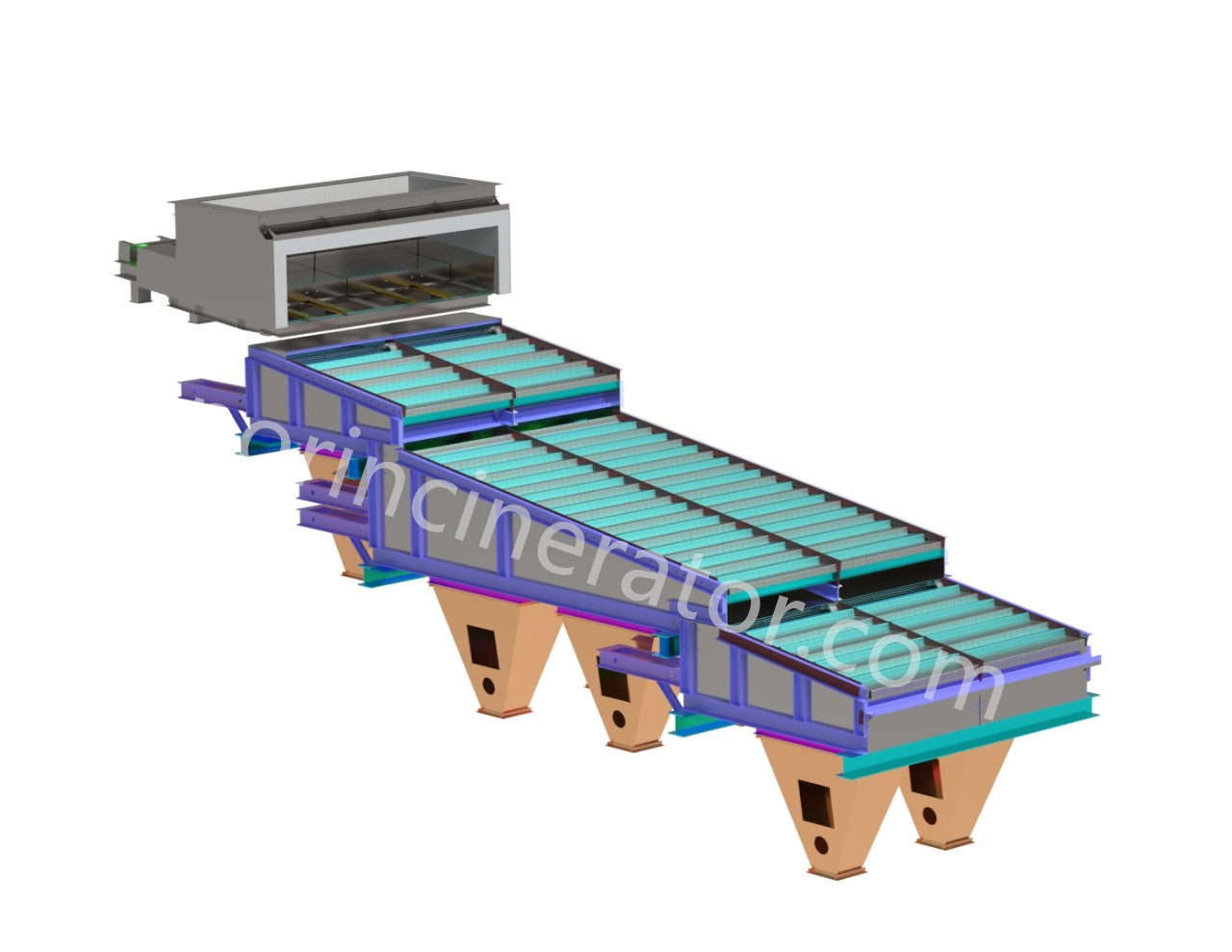

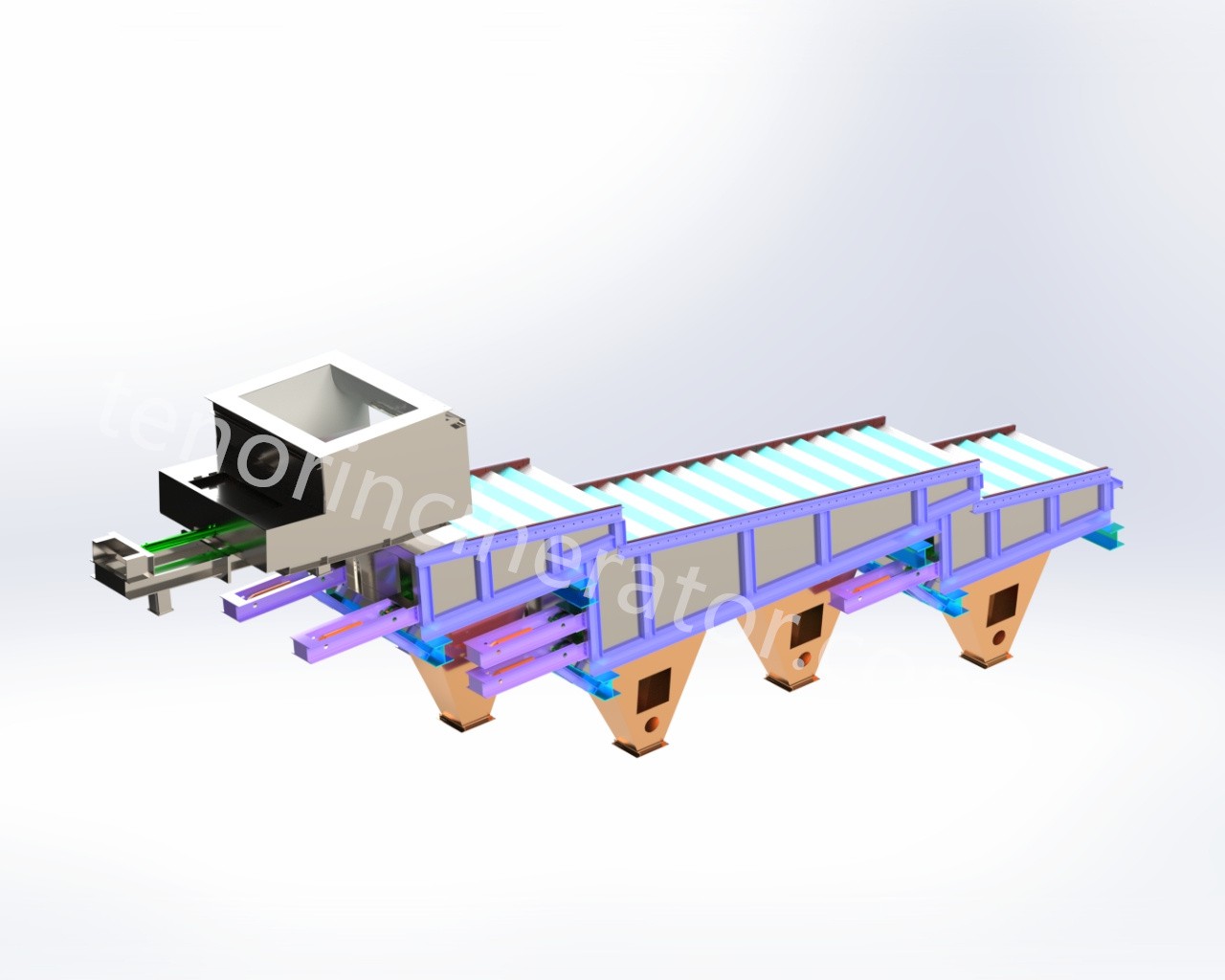

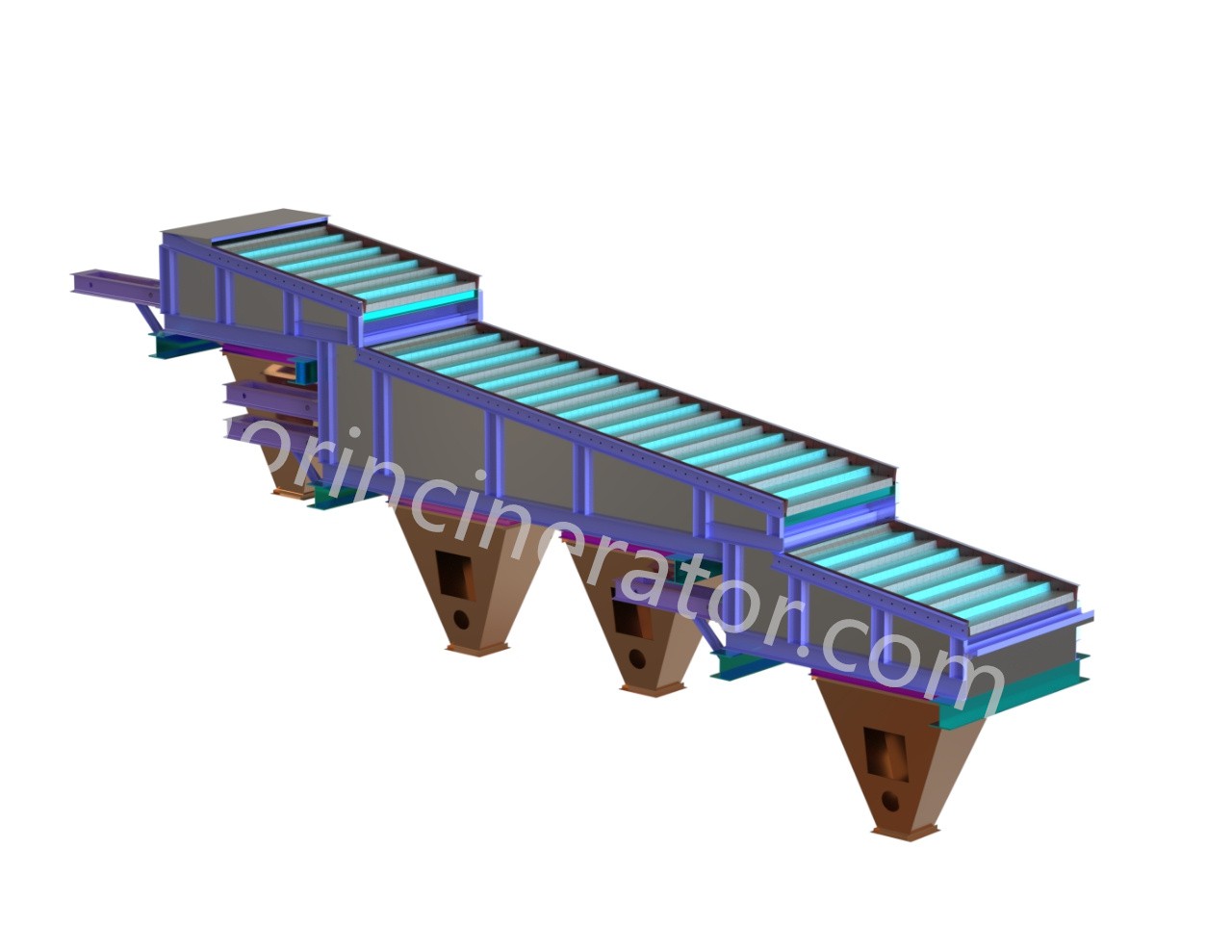

Step Grate

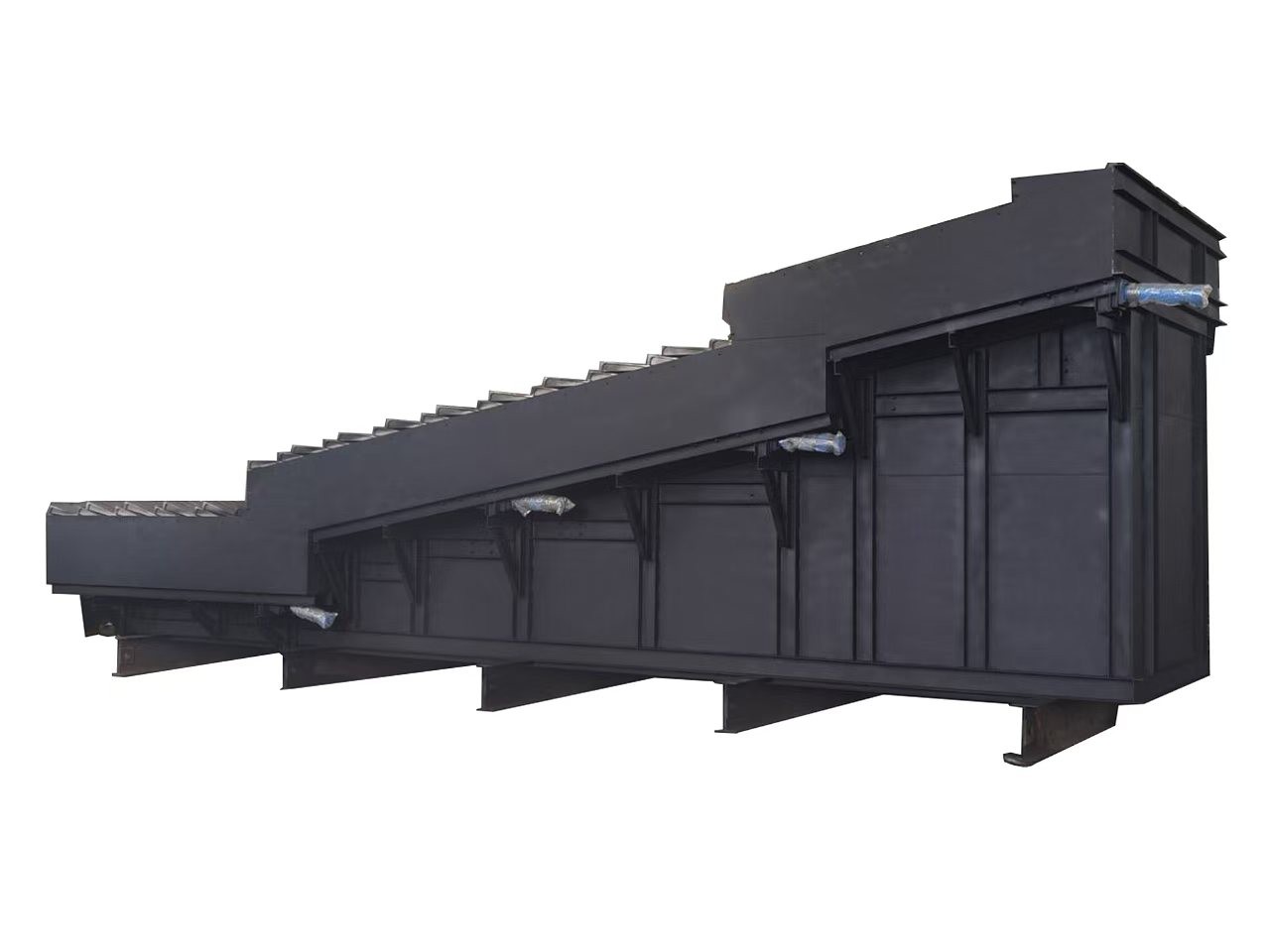

Tenor garbage incineration grate is a downward-pushing stepped inclined reciprocating grate, the grate is divided into three stages of drying, combustion and burning out, and a height difference is set between each section of the grate, so that the garbage is scattered after falling and the garbage is pushed to move, and at the same time the garbage is prevented from gathering together to lead to incomplete combustion. The step grate is driven by hydraulic cylinders, and the three sections of the grate can be controlled independently, so that the movement cycle of the grate can be adjusted according to the combustion state in the furnace. The grate is made of heat-resistant cast steel, which has good wear-resistant, high temperature-resistant and corrosion-resistant properties.

What is the market application prospect of reciprocating stepped grates?

In the field of waste incineration, reciprocating step grates offer many advantages. For example, the three-step drop reciprocating grate is well-suited for the hot air furnaces used in waste incinerators. Waste enters the downward-inclined grate through the feed hopper, and due to the alternating movement of the grates, the waste is pushed downward. This allows the waste to pass through each section of the grate in sequence until it is fully incinerated and discharged from the furnace. Combustion air enters from beneath the grate and mixes with the waste, making it particularly suitable for low-calorific, high-moisture fuels such as domestic waste and biomass. The reciprocating grate has a strong pushing effect, which makes it ideal for incinerating low-calorific coal, various biomass materials, and high-ash urban waste.

The reciprocating step grate demonstrates significant advantages in the fields of waste incineration and biomass combustion. With rising environmental protection standards and advances in industry technology, its market application prospects are very promising.

Advantages of Reciprocating Step Grates in Urban Domestic Waste Treatment

Minimal Pretreatment of Waste: Urban domestic waste does not require extensive pretreatment, such as strict screening, crushing, or other complex processes. It only needs to settle naturally in the storage pit, be compressed and dehydrated, and partially fermented before entering the furnace for combustion. This feature significantly reduces the initial costs and workload associated with waste treatment.

Segmented Combustion Process: The combustion on a reciprocating step grate occurs in stages, similar to that of a chain grate. By using segmented air supply and appropriately adding secondary air, the waste goes through various stages—drying, distillation, volatile matter ignition, coke combustion, and ash burnout—to ensure thorough combustion. For instance, some urban domestic waste incineration power plants use the reciprocating step grate process. Here, urban waste is delivered to the plant by specialized trucks, automatically weighed at the weighbridge station, and unloaded into the closed, slightly negative-pressure waste pool. After a period of storage, fermentation, and dehydration, the waste is sent to the reciprocating step grate for incineration, achieving waste reduction, harmless treatment, and resource recovery.

Simple Structure and Effective Smoke and Dust Removal: The reciprocating step grate features a simple structure, is easy to manufacture, consumes little metal, and has good smoke and dust removal capabilities. It is widely used in small industrial boilers and represents a combustion technology with growth potential. Typically, the grate is strip-shaped or plate-shaped and is fixed at the bottom of the furnace or combustion chamber using surrounding frames. While its operation may involve a higher level of manual labor, it offers certain cost advantages for small- to medium-sized urban domestic waste treatment projects.

trong Adaptability: The reciprocating step grate is highly adaptable and can handle the complex composition, low calorific value, instability, and high moisture content of urban domestic waste. By adjusting the residence time of waste and flue gas within the furnace, the formation of secondary pollutants can be minimized, and stable combustion of the waste can be ensured.

Reinforcement before shipment

Our Service Processes

Pre-sales Consultancy

1

>>

Confirmation of order

2

>>

Production

3

>>

Multi-Channel Shipping

4

>>

Confirmation of recei

5

>>

After-sale Services

6

Turning trash into treasure, sustainable energy from small-scale incineration.

Our address

No.2 Honggang Road, Ganjingzi District, Dalian City, Liaoning, China.

Phone Number

+86-15382281005

E-mail: sales@gyxh.net

As one of the most professional furnace suppliers in China, we're featured by quality products and good service. Please rest assured to buy high-grade furnace made in China here from our factory.

sorting center waste incinerator, waste rotary kiln incinerator, municipal waste incinerator