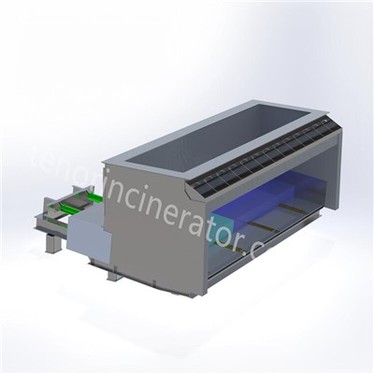

Fuel Feeding System

Tenor Low Carbon New Energy Technology (Liaoning) Co., Ltd. was founded in 2021, the company is located in Dalian City, Dalian University of Technology Industrial Incubation Park, the production base is located in Yantun, Paoai Village, Wafangdian City, Liaoning Province. Our company covers a total area of 500,000 square meters, more than two hundred employees, with fixed assets of 500 million yuan, more than 400 sets of major production equipment, machining, riveting and welding, casting, assembling and other production workshops, with two advanced The company has two advanced Disha casting production lines in Denmark, supporting automatic spheronization automatic equipment and spectral monitoring equipment, and the quality of products is at the leading level in China.

The company's main business includes the Design, Production, Technology development and Sales of complete sets of waste incineration treatment equipment, the company has long cooperated closely with Harbin Institute of Technology, Dalian University of Technology, Nanjing University of Science and Technology and other renowned universities, with reliable professional technical support, experienced design team, to provide customers with high-quality products.

01

High Quality

02

AdvancedEquipment

03

Professional Team

04

Custom Service

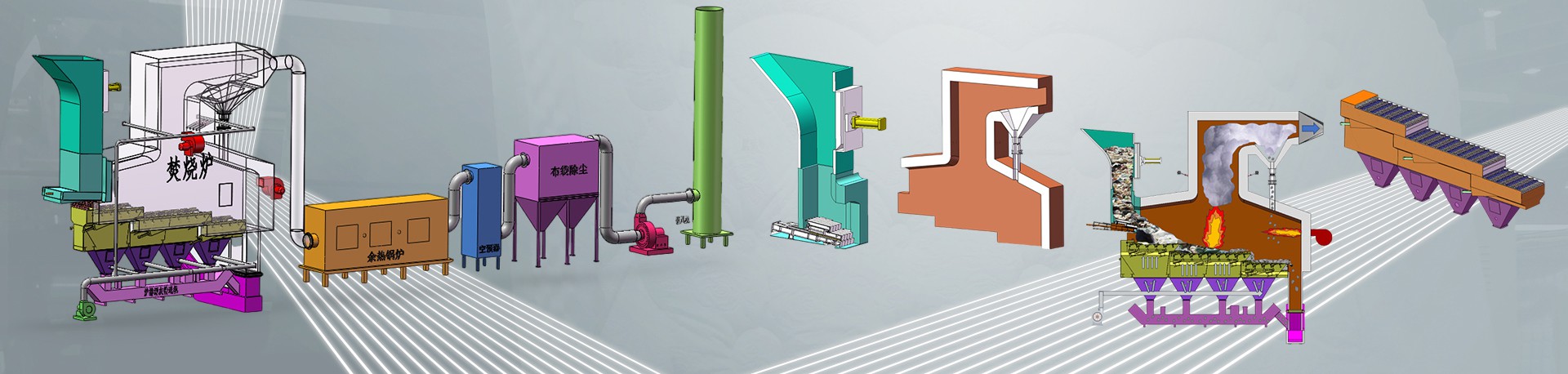

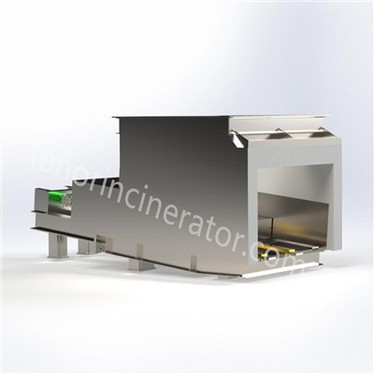

Products Description

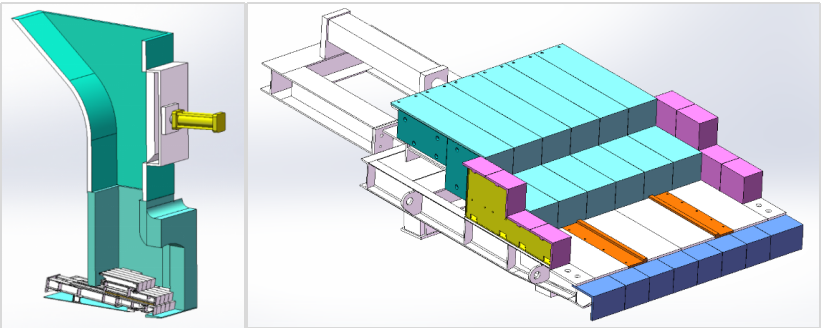

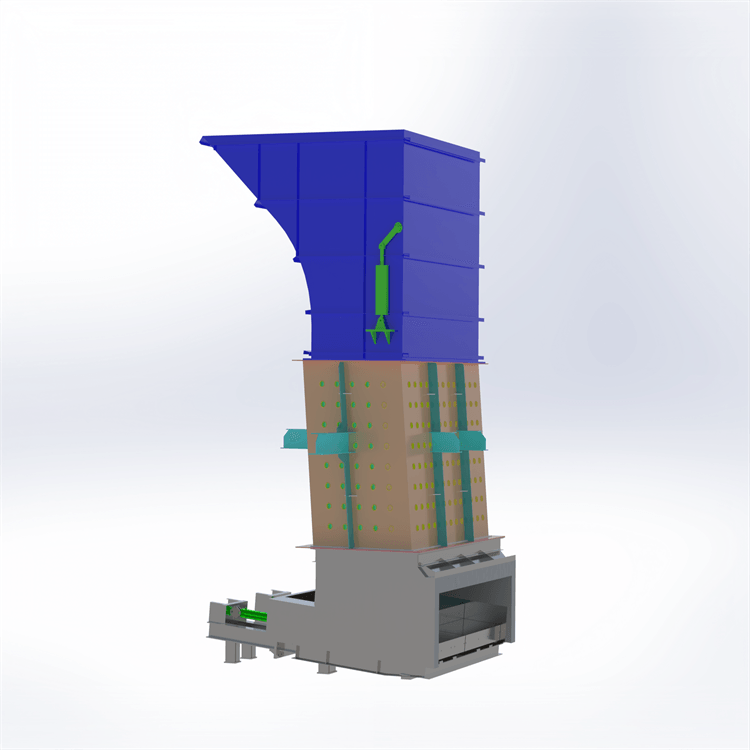

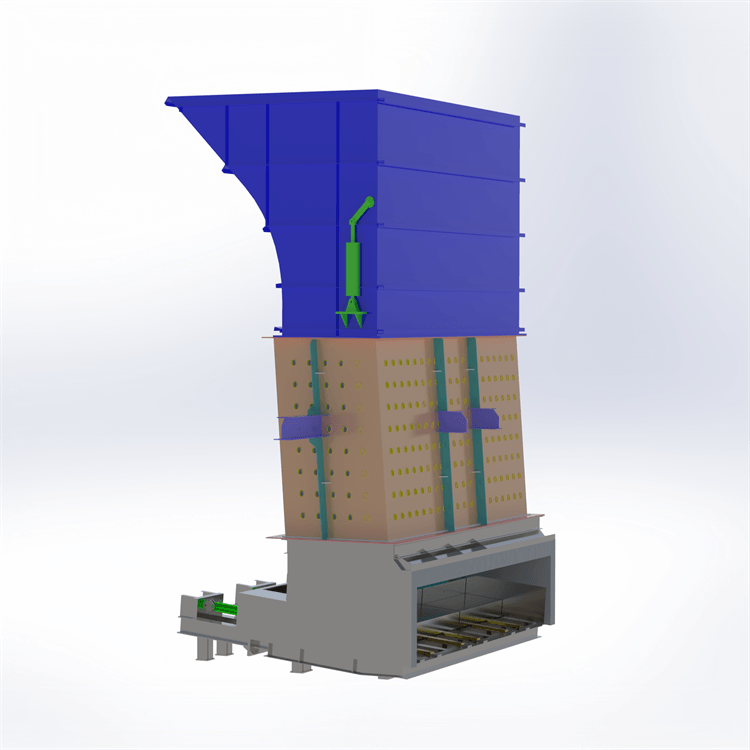

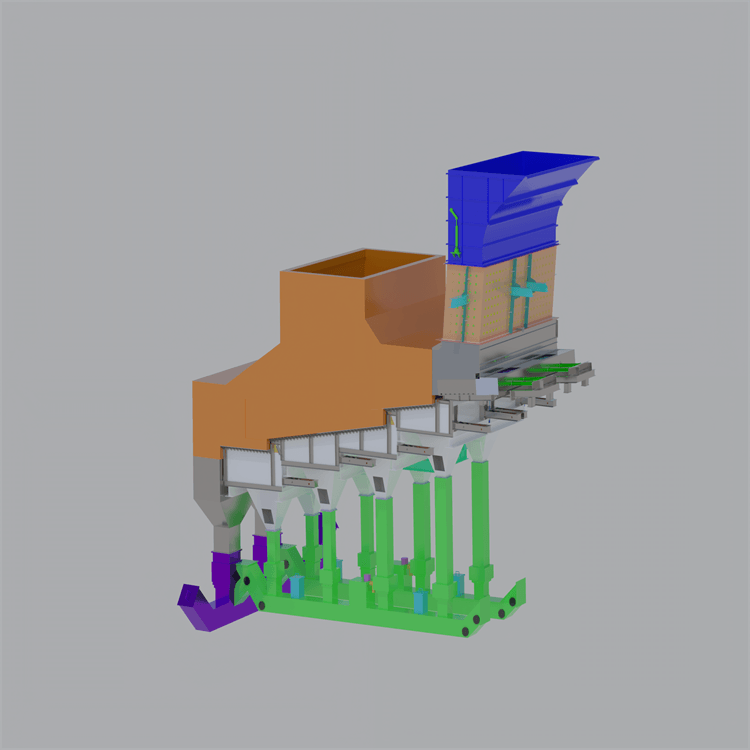

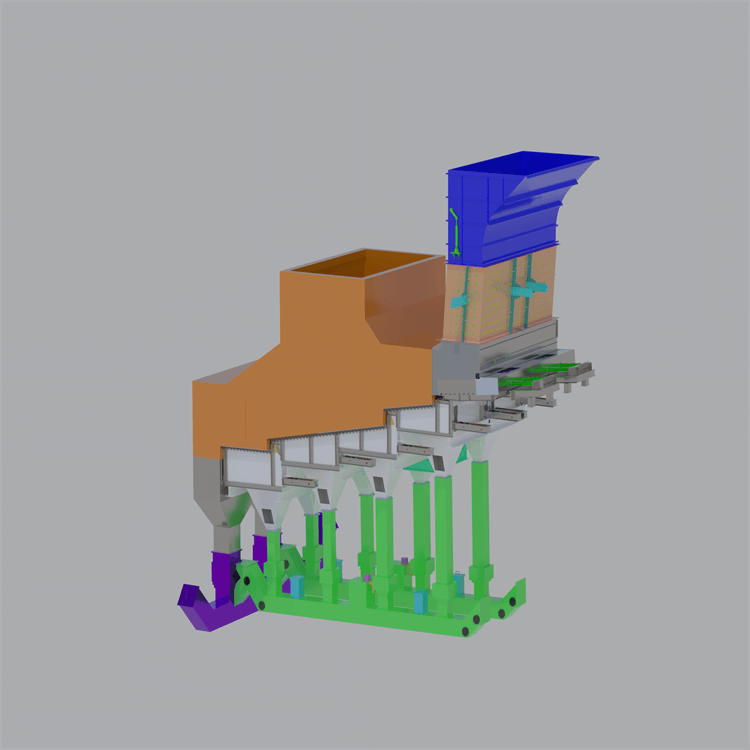

Feeding system consists of hopper and feeder, hopper internal gate, the gate to ensure the sealing at the same time to take into account the function of breaking the bridge, in the garbage clusters bridge blocked hopper through the gate movement to realize the bridge. The feeder and the gate are driven by cylinders to push a certain amount of garbage into the incinerator through periodic reciprocating push and pull movements, and the feeder can adjust the feeding speed according to the load of the incinerator.

What is fuel feeding system?

The fuel feeding system is a critical component of the boiler operation and energy production process. A steady fuel flow facilitates easier control of the combustion process. There are various types of fuel feeding systems depending on the size and type of the power plant.

Fuel Feeder Systems

Steady and continuous fuel feeding in waste-to-energy plants is key to stable operation, maximum efficiency, and lower operational and maintenance costs.

No Pre-treatment Required

In our waste-to-energy plants, there is no need to pre-treat the waste. This not only saves time but also reduces both operational and maintenance costs.

Steady Energy Production

The feeding of waste onto the grate must be continuous and adjusted to the grate’s transport capacity. Our technology ensures an even fuel layer across the grate, ensuring steady energy output and maximum efficiency.

Continuous Waste Transport with No Clogging

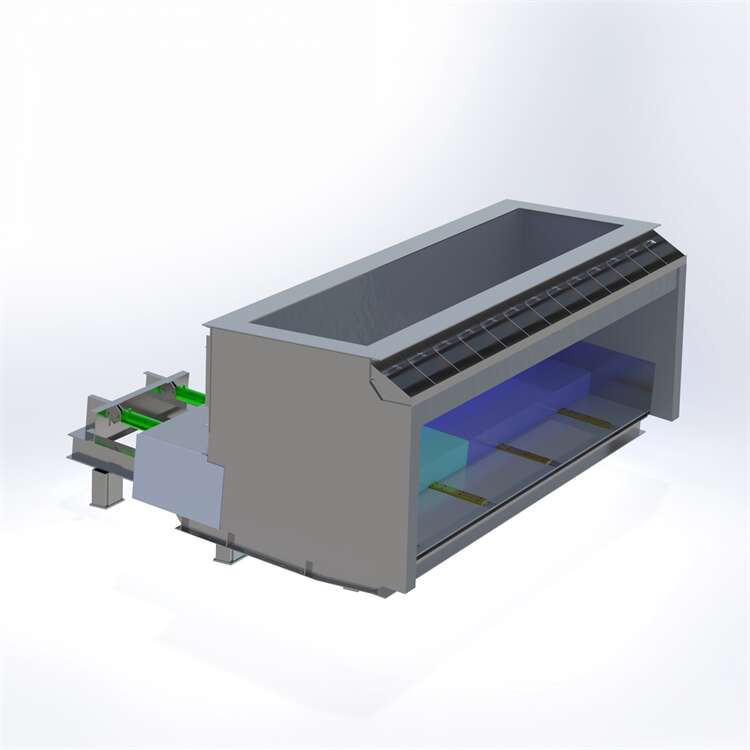

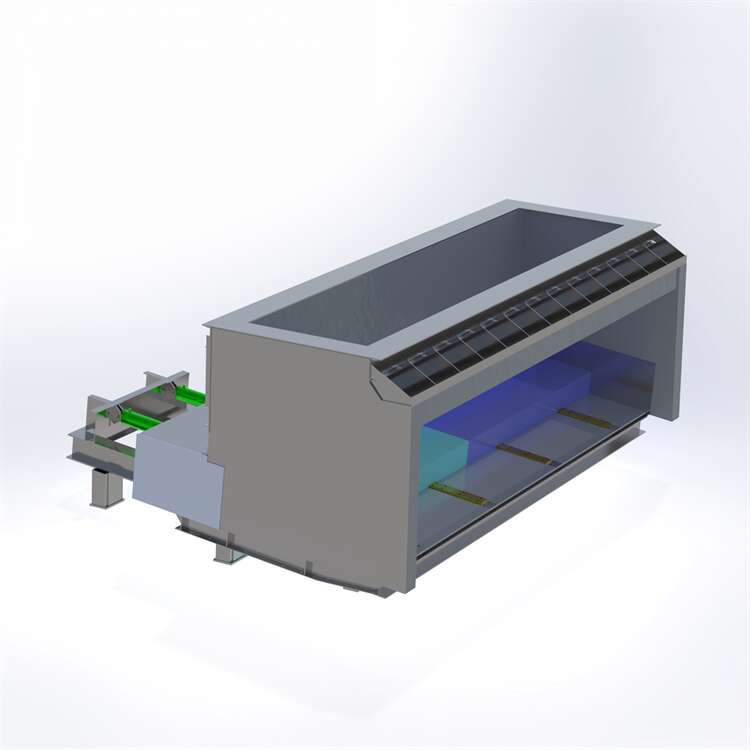

We design our feed hoppers to enable continuous waste transport to the water-cooled chute without clogging, resulting in fewer shutdowns and more consistent plant operation.

Hydraulic Dampers Ensure Safety During Start-up and Shutdown

During plant start-up and shutdown, two powerful, hydraulically operated dampers are engaged. Positioned between the chute and hopper, these dampers automatically close in the event of a power failure and can be manually closed in the event of a fire in the chute.

Changeable Wear Plates = Lower Maintenance Costs

The grate is fed at a variable rate, adapted to energy production, by means of a hydraulically operated pusher. Changeable wear plates cover the front and top of the feed pusher. The sides of the water-cooled feed chute are protected by changeable cast-iron plates, extending to the top of the feed pusher, which helps to reduce maintenance costs.

Feed Flexibility Ensures Optimal Efficiency and Minimum Wear

The continuous, slow movement of the feed pusher can be adjusted according to energy production and combustion control, providing a steady, continuous waste feed onto the grate. This ensures maximum efficiency and minimizes wear.

project case

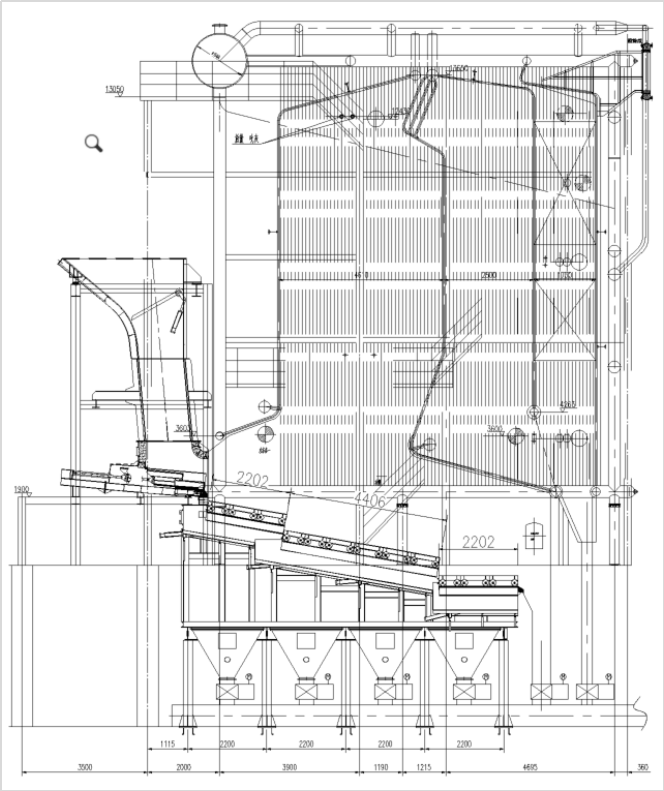

Ho Chi Minh City, Vietnam, 600t/d Waste Incineration Power Generation Project (large waste incineration power generation project)

The 600t/d waste incineration power generation project in Ho Chi Minh City, Vietnam uses our three-step inclined reciprocating grate furnace for daily treatment of 600t waste, with 75t/h steam boiler +18MW generator set. The project is currently under construction and is scheduled to be put into operation in December, 2024.

Thank you for visiting our website. We hope you can find products that meet your needs. We can also customize a complete solution for you according to your needs.Please contact us.

As one of the most professional fuel feeding system suppliers in China, we're featured by quality products and good service. Please rest assured to buy high-grade fuel feeding system made in China here from our factory.

waste incinerator garbage, waste incinerator burner, paper waste incinerator