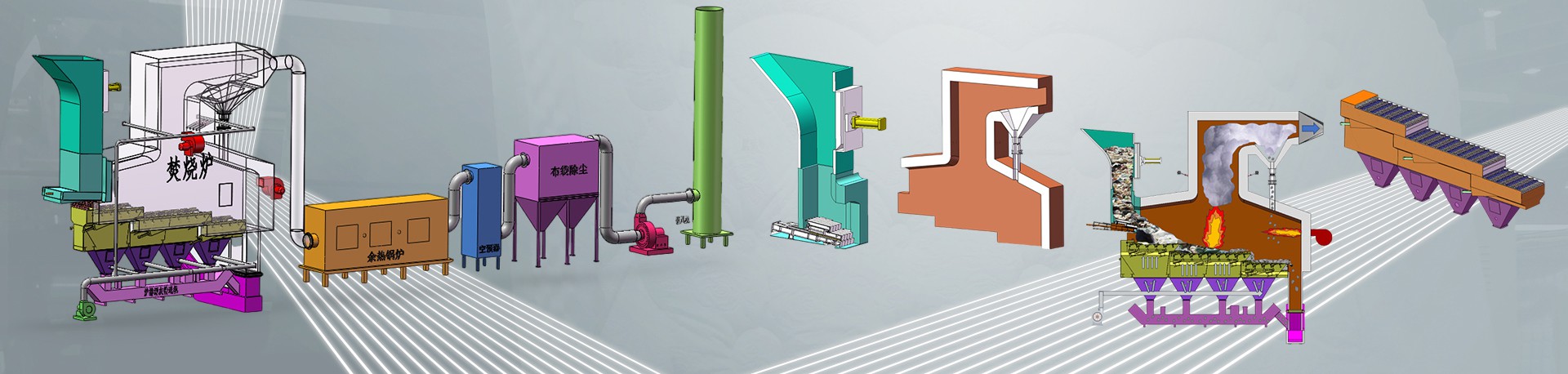

Slag Removing System

Tenor Low Carbon New Energy Technology (Liaoning) Co., Ltd. was founded in 2021, the company is located in Dalian City, Dalian University of Technology Industrial Incubation Park, the production base is located in Yantun, Paoai Village, Wafangdian City, Liaoning Province. Our company covers a total area of 500,000 square meters, more than two hundred employees, with fixed assets of 500 million yuan, more than 400 sets of major production equipment, machining, riveting and welding, casting, assembling and other production workshops, with two advanced The company has two advanced Disha casting production lines in Denmark, supporting automatic spheronization automatic equipment and spectral monitoring equipment, and the quality of products is at the leading level in China.

01

High Quality

02

AdvancedEquipment

03

Professional Team

04

Custom Service

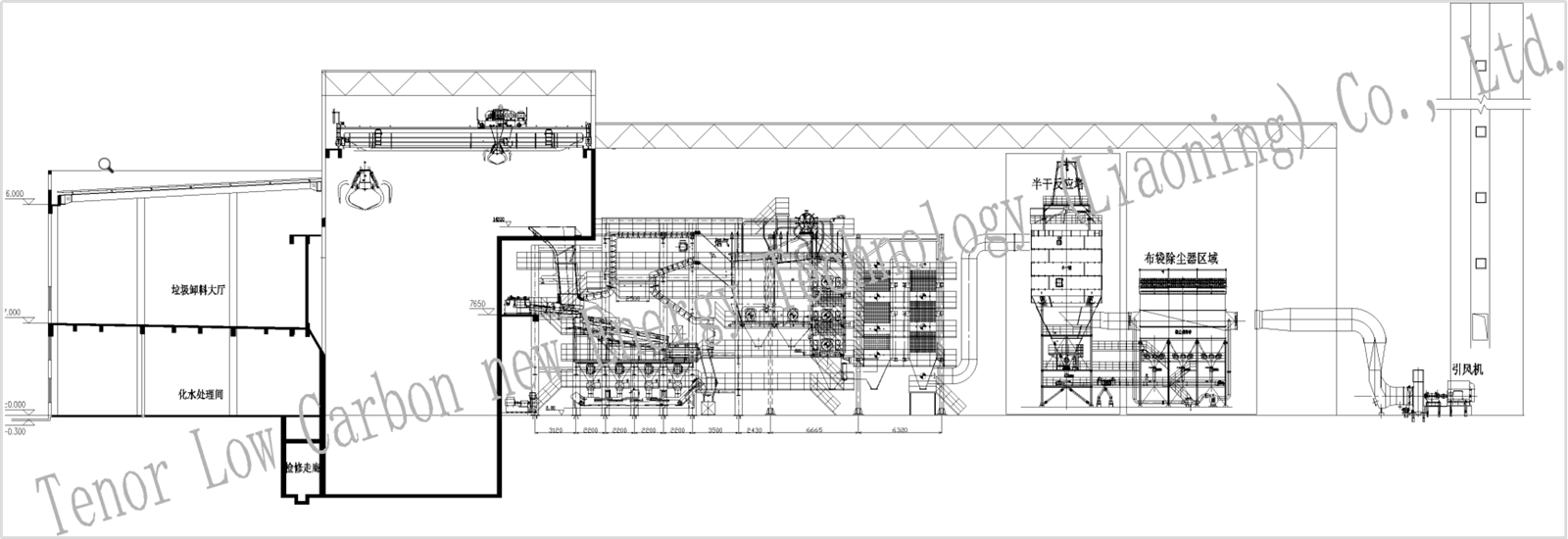

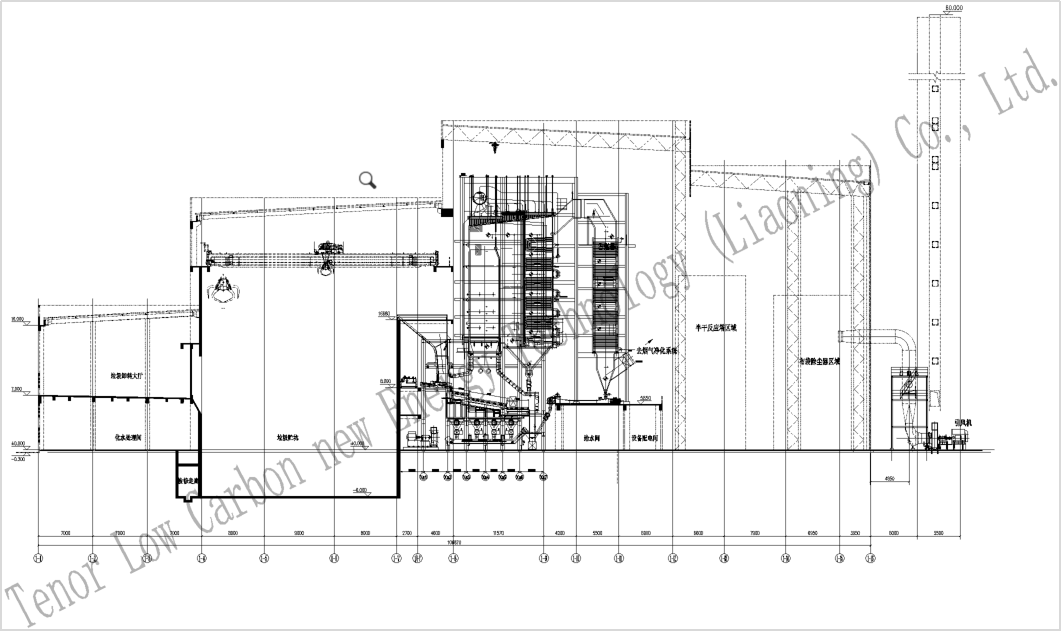

What is the working principle of ash conveyor and slag remover?

The ash system consists of an under-furnace ash hopper (cum air chamber), a horizontal ash conveyor, and a slag remover. The small amount of fine ash produced after complete waste combustion falls into the ash hopper through the grate gap and then collects in the horizontal ash conveyor. The main ash produced by waste combustion is pushed into the slag bucket through the grate of the combustion section, and then enters the wet slag remover together with the fine ash. All the ash is sent to the slag pit by the slag remover.

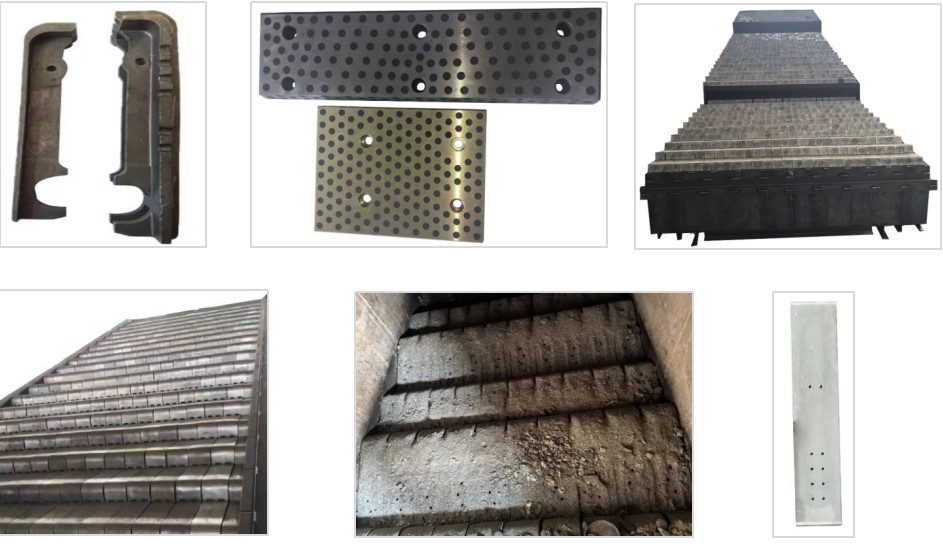

Components of the Slag Removal System

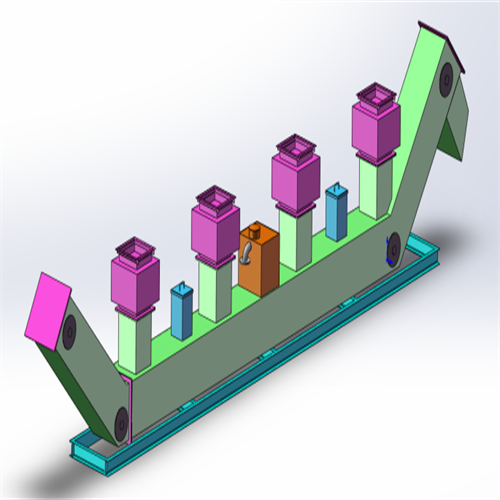

Slag Discharging Machine

Usually, mechanical conveying equipment is used, such as a scraper slag discharging machine or a chain bucket slag discharging machine. Its main function is to remove slag from the bottom of the furnace after incineration.

The scraper slag discharging machine consists of a scraper, a chain, and a drive device. Driven by the chain, the scraper drags the slag from the bottom of the furnace and transports it to the slag pit or subsequent processing equipment.

The chain bucket slag discharging machine transports the slag from the bottom of the furnace by lifting and moving the chain bucket.

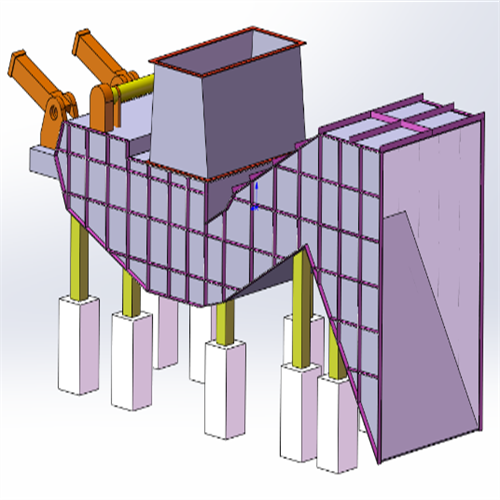

Slag Pit

The slag pit is used to temporarily store slag discharged from the incinerator. It typically has sufficient capacity to support the continuous operation of the incinerator.

A ventilation system is usually installed in the slag pit to remove heat and harmful gases emitted by the slag. This system also prevents the accumulation of combustible gases, which could lead to safety hazards.

Slag Processing Equipment

This includes crushers, magnetic separators, and screening machines, which are used to further process the slag and facilitate resource recycling.

The crusher breaks down large slag into smaller particles for easier processing and transportation. The magnetic separator extracts metal substances, such as iron and steel, from the slag for recycling. The screening machine sorts the slag by particle size for separate processing.

Process Characteristics

Simple structure, easy to operate and maintain

Even air distribution of the grate, uniform combustion of garbage

Equipment modularization, easy installation, short construction period

lThe grate is resistant to high temperature, corrosion and abrasion, with low replacement rate

Adequate garbage incineration, thermal scorch reduction rate ≤5%

The equipment is fully automated

Scope of Services

What are the maintenance precautions for the slag removal system of the waste incinerator?

1. Maintenance of the Slag Discharger

Regular Inspection

Check the wear of the scraper, chain, drive device, and other components. If the scraper is deformed, the chain is loose, or the drive device is malfunctioning, repairs or replacements should be made promptly.

Inspect the sealing of the slag discharger to ensure no slag leaks into the surrounding environment. If the seal is damaged, it should be replaced in a timely manner.

Lubrication and Maintenance

Regularly lubricate the transmission parts of the slag discharger, such as chains and gears. Choose an appropriate lubricant and apply it according to the prescribed lubrication schedule to reduce wear and friction.

Ensure the cleanliness of the grease to prevent impurities from entering the lubrication system and affecting its effectiveness.

Cleaning and Maintenance

Regularly remove slag and debris from inside the slag discharger to prevent blockages and maintain optimal equipment operation. A high-pressure water gun or specialized cleaning tools can be used for this purpose.

Clean the area around the slag discharger to keep the equipment tidy and prevent slag accumulation, which can interfere with heat dissipation and ventilation.

2. Maintenance of the Slag Pit

Ventilation System Maintenance

Regularly check the ventilation system in the slag pit to ensure proper airflow. Remove dust and debris from ventilation ducts and fans to maintain smooth air circulation.

Inspect the tightness of the ventilation system to prevent harmful gas leaks. If any seals are found to be loose, they should be repaired promptly.

Slag Pit Cleaning

Periodically clean the slag in the pit to prevent excessive buildup that could interfere with the normal operation of the slag discharger. Mechanical equipment such as a loader can be used for cleaning.

During slag pit cleaning, take safety precautions to prevent accidents, such as collapse. Additionally, the cleaned slag should be transported to a designated treatment site without delay.

3. Maintenance of Slag Handling Equipment

Crusher Maintenance

Regularly inspect the wear of the hammer head, liner, and other wear parts of the crusher. If severe wear is detected, replace these parts promptly to maintain crushing performance.

Check the crusher's transmission components, such as belts and gears, to ensure they are functioning correctly. If abnormalities are detected, they should be repaired or replaced immediately.

Lubricate the crusher regularly to ensure its optimal performance.

Magnetic Separator Maintenance

Regularly clean the adsorbents from the magnetic drum surface of the magnetic separator to maintain effective magnetic separation. A high-pressure water gun or specialized cleaning tools can be used for this task.

Inspect the magnetic separator's transmission parts and control system to ensure normal operation. If faults are found, repairs should be made in a timely manner.

Screening Machine Maintenance

Periodically inspect the screen of the screening machine for wear. If damage is detected, replace the screen promptly to ensure effective screening.

Check the vibration motor and transmission parts of the screening machine to ensure they are operating normally. If any issues are identified, they should be repaired or replaced as needed.

4. Overall System Maintenance

Safety Inspection

Conduct regular safety inspections on the slag removal system, including checking the grounding of equipment and the integrity of protective devices. Ensure the safe operation of the system and prevent accidents.

Provide safety training for operators to enhance their awareness of safety protocols and improve their operational skills.

Operation Monitoring

Establish an operational monitoring system for the slag removal process and regularly record key equipment parameters, such as temperature, pressure, and current. By analyzing these parameters, potential issues can be identified early, and corrective actions can be taken.

Monitor the system's operating status. If abnormal noises, vibrations, or leaks are observed, stop the equipment for inspection immediately, and only resume operation once the problem has been resolved.

Spare Parts Management

Implement a spare parts management system to maintain an adequate inventory of spare parts based on the equipment's usage and maintenance needs. This ensures timely replacement of faulty parts and minimizes downtime.

Organize and label spare parts properly to avoid loss or damage, ensuring they are stored in an appropriate manner.

As one of the most professional slag removing system suppliers in China, we're featured by quality products and good service. Please rest assured to buy high-grade slag removing system made in China here from our factory.

waste incinerator burner, waste incinerators for sale, solid waste incinerator