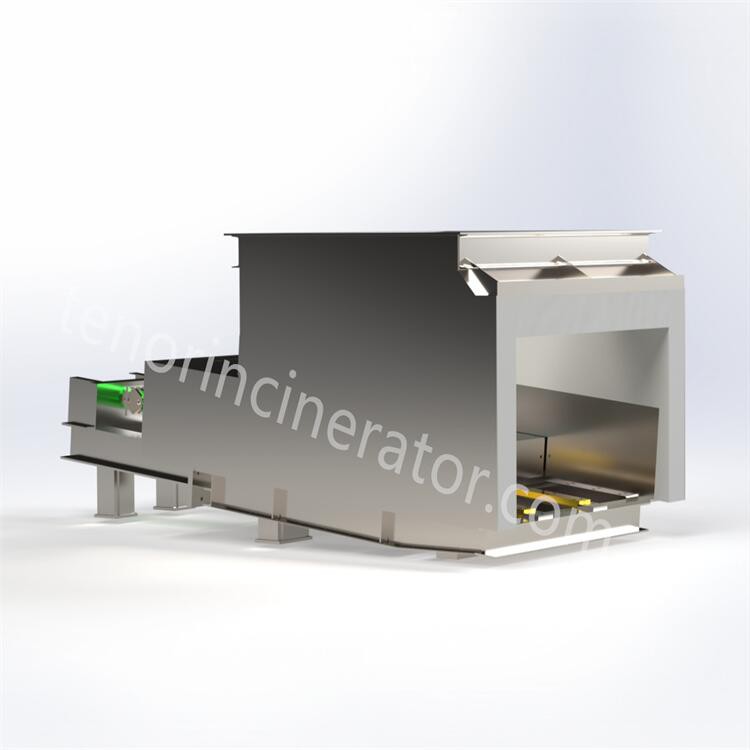

Products Description

Performance Features:

High Thrust Force: The hydraulic system can provide strong thrust force, enabling the pusher to handle a large amount of waste materials and overcome the resistance encountered during the pushing process. This is especially important for incinerators that deal with various types of waste, including those that are high-density or bulky.

Precise Control: The hydraulic system allows for precise control of the pushing speed and stroke of the push plate. This enables the operator to adjust the pushing process according to the specific requirements of the incinerator and the characteristics of the waste materials, ensuring the uniformity and stability of the feeding process.Reliable Operation: With proper design and manufacturing, the incinerator hydraulic pusher has high reliability and durability. It can operate continuously for long periods under the harsh working conditions of the incinerator, with a low failure rate and easy maintenance.

Application Scenarios:

Waste Incineration Plants: It is widely used in various waste incineration plants, such as municipal solid waste, industrial waste, and medical waste incineration plants. It plays a vital role in ensuring the continuous and stable operation of the incinerator by accurately and efficiently pushing waste materials into the furnace.

Other Related Industries: In addition to the waste incineration industry, the hydraulic pusher can also be applied in other industries that require the pushing or conveying of materials, such as the metallurgical and chemical industries; however, its specific design and application need to be adjusted according to the characteristics of the materials in different sectors.

1. Powerful thrust:

The hydraulic system provides a strong driving force, enabling the pusher to handle a large amount of waste materials and having the ability to push even bulky or heavy waste effectively. This is especially important for ensuring the continuous feeding of the incinerator and maintaining the normal operation of the incineration process.

It can overcome the resistance encountered during the pushing process, such as the friction of waste materials and the pressure in the incinerator, to ensure the smooth progress of the pushing work.

2. Precise control:

The hydraulic system allows for accurate control of the pushing speed, stroke, and frequency of the pusher. Operators can adjust these parameters according to the specific requirements of the incinerator and the characteristics of the waste materials, achieving precise control of the feeding process.

This helps to ensure the uniformity and stability of waste feeding, which is beneficial to the efficient combustion of waste in the incinerator and improves the overall incineration efficiency.

3. High adaptability:

It can adapt to different types of waste materials, including those with high viscosity, high moisture content, or irregular shapes. Whether it is municipal solid waste, industrial waste, or other special waste, the hydraulic pusher can handle them effectively.

It can also adapt to the working environment of high temperature and harsh conditions in the incinerator, ensuring reliable operation under such circumstances.

4. Reliable operation:

The structure of the hydraulic pusher is relatively stable, and the components are made of high-quality materials, which can withstand the long-term operation and heavy workload in the incinerator environment, with a low failure rate.

The hydraulic system has good sealing performance, which can effectively prevent the leakage of hydraulic oil and ensure the normal operation of the equipment, reducing the risk of environmental pollution and equipment damage caused by oil leakage.

5. Long service life:

The wear resistance and corrosion resistance of the key components of the hydraulic pusher are relatively high, which can maintain good performance for a long time under the condition of continuous use. Through regular maintenance and proper use, its service life can be further extended.

6. Easy maintenance:

Although the hydraulic pusher is a complex mechanical and hydraulic equipment, its structure is relatively modular, which makes maintenance and repair more convenient. When a failure occurs, it is easier to locate and replace faulty components, reducing the downtime of the equipment and maintenance costs.Is there any grammatical error in this passage? Is it a literal translation from Chinese to English? If there are any errors, please correct the grammar without changing the original meaning.

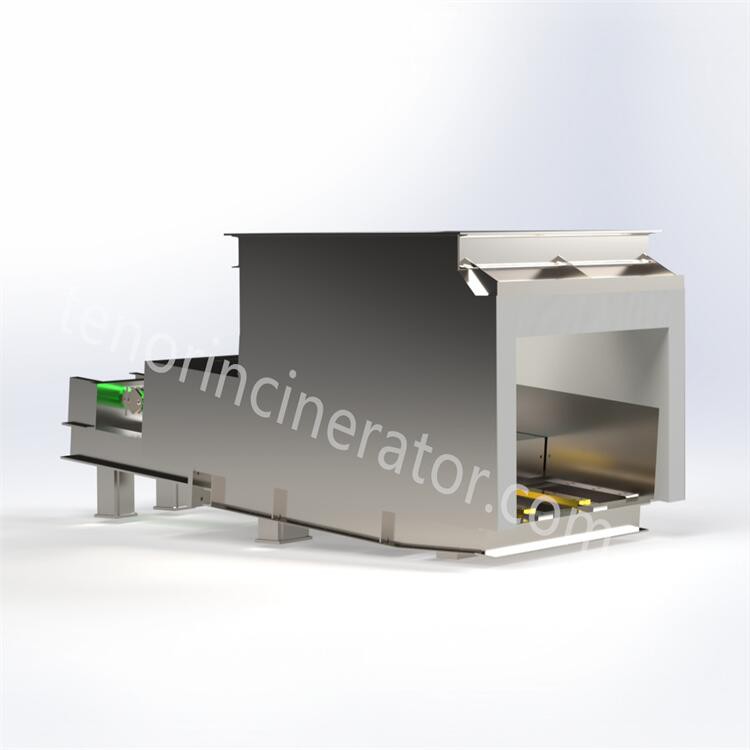

Our hydraulic pusher:

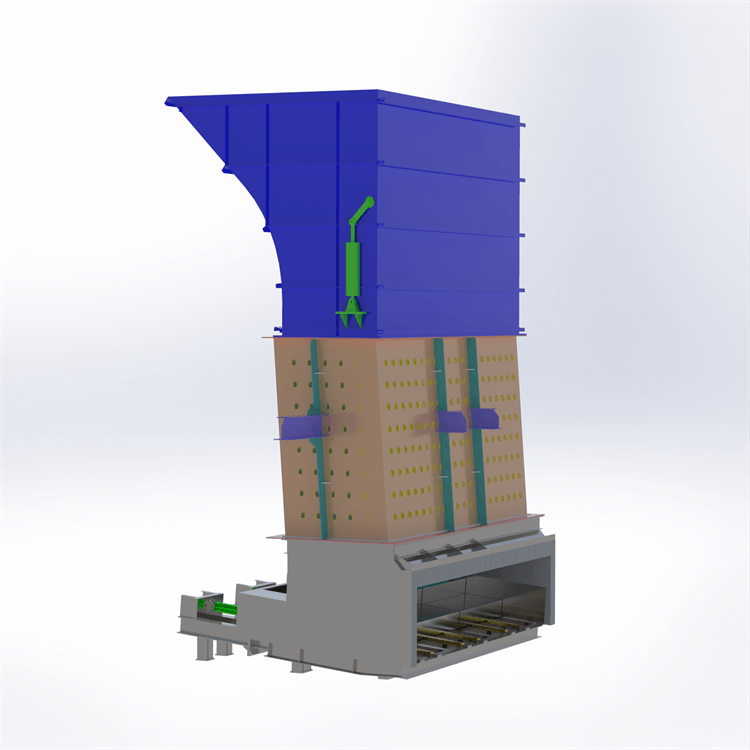

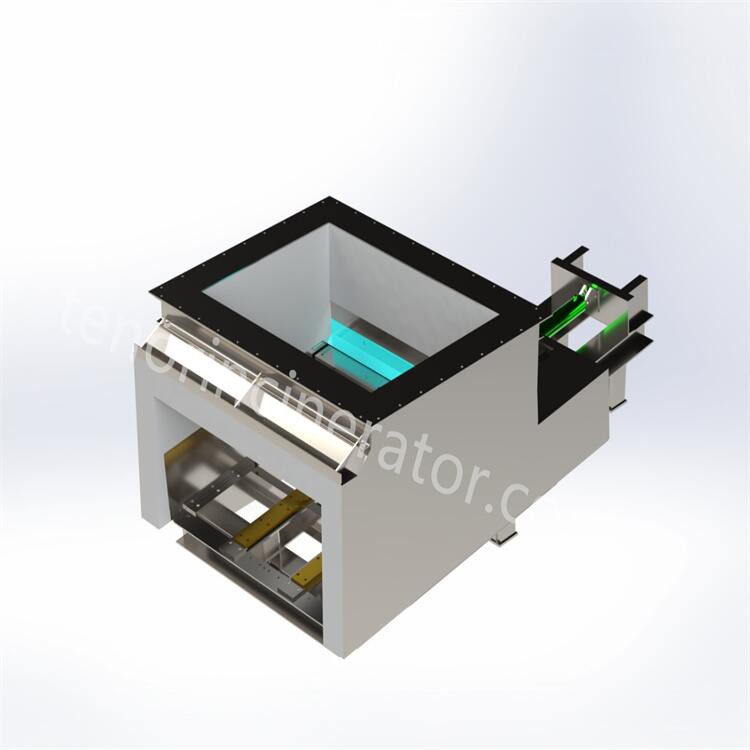

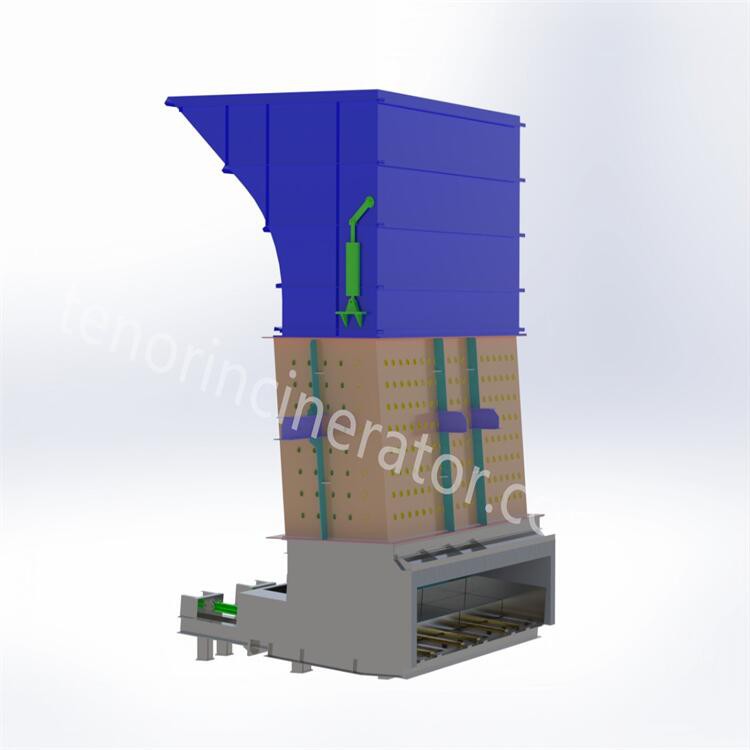

Process Characteristics

Simple structure, easy to operate and maintain

The grate is resistant to high temperature, corrosion and abrasion, with low replacement rate

Even air distribution of the grate, uniform combustion of garbage

Adequate garbage incineration, thermal scorch reduction rate ≤5%

Equipment modularization, easy installation, short construction period

The equipment is fully automated.