Tenor Low Carbon new Energy Technology (Liaoning) Co., Ltd. ,Production base is located in Wafangdian City and covers an area of 500,000 ㎡. There are more than 500 employees (including 60 R&D technicians) and more than 350 main production equipment (including Denmark Disha casting production lines.

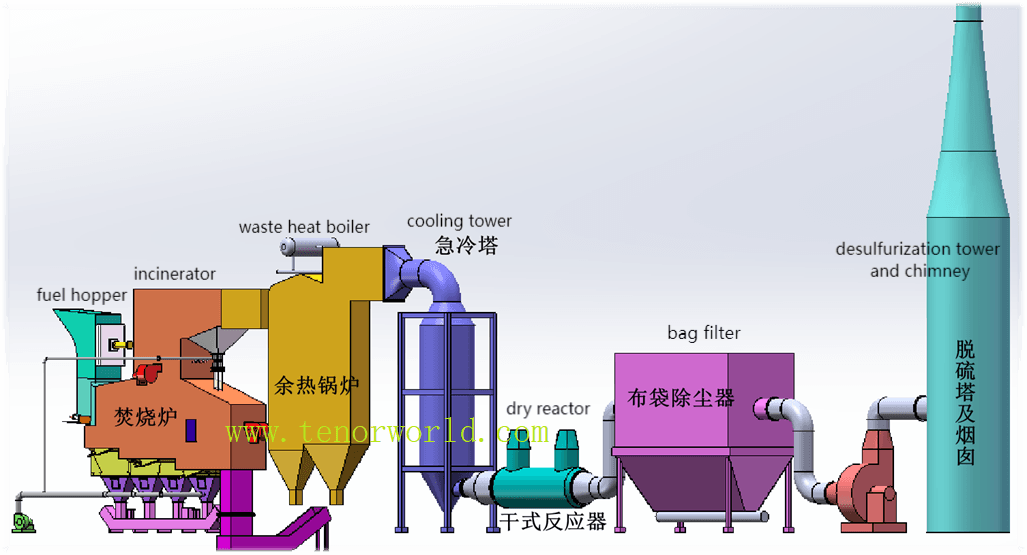

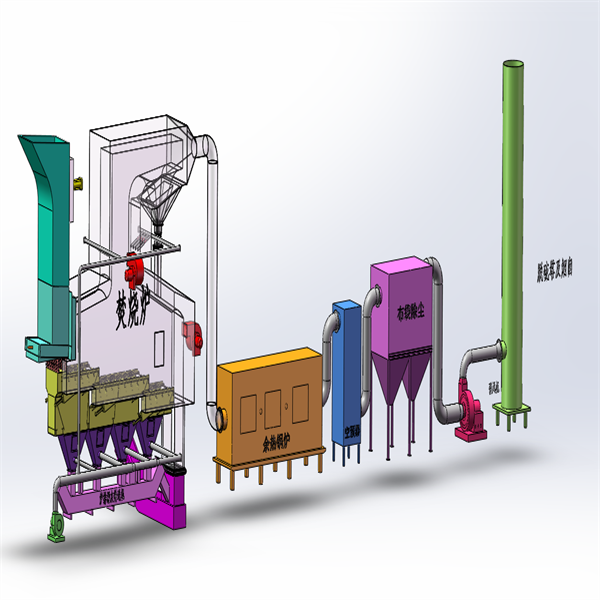

Daily capacity 50 to 250 tons of small domestic waste incinerator, complete MSW incineration system,agricultural Waste strategy, one-stop solution of WTE.

01

High Quality

02

Advanced Equipment

03

Professional Team

04

Custom Service

What we do best?

Goals give us focus!

Devote all our efforts to Support Customers.

We respect, support and trust each other, Always Strengthen Our TEAM Relationships. Provide the highest level of professionalism in planing and delivering services to our clients.

Technical solution: to be pre-engineered technical solutions to provide fast response, cost saving, low maintenance and longer operating life of all project conditions and requirements.

Products Parameters

|

Scale (t/d) |

Number of furnaces |

Overall height of equipment (m) |

Floor space (m2) |

Emission standard |

|

50 |

1 |

17 |

60 |

《Pollution control standards for household waste incineration》 (GB18485-2014) |

|

100 |

1 |

17 |

75 |

|

|

150 |

2 |

17 |

90 |

|

|

200 |

2 |

17 |

105 |

|

|

250 |

3 |

17 |

120 |

What Our Clients Say

Advantages of Horizontal Placement of Combustion Chamber and Waste Heat Boiler

Structural simplification

The horizontally arranged combustion chamber and waste heat boiler can simplify the structural design and reduce complexity, thereby reducing manufacturing and installation costs.

Space utilization

Horizontal arrangement helps to utilize space more efficiently, especially under limited site conditions, and can reduce the floor area.

Ease of maintenance

Equipment arranged horizontally is easier to maintain and service as they are generally more accessible, which can reduce maintenance costs.

Thermal efficiency

The horizontal arrangement of waste heat boilers can optimize the recovery and utilization of heat energy and improve the thermal efficiency of the entire system.

Cost-effectiveness

By optimizing the design, the amount of material used can be reduced, and manufacturing and transportation costs can be reduced.

Safety

In some cases, a horizontal arrangement may help improve the safety of the system because it reduces the vertical height of hot components, thereby reducing heat loss and potential safety risks.

ADVANTAGES of Our Incinerator

- Simple structure, easy operation.

- The grate is resistant to high temperatures, corrosion, and wear, and has a low replacement rate.

- The grate distributes air evenly and the garbage burns evenly.

- The waste combustion is sufficient, and the heat burn reduction rate is less than 5%.

- The equipment is modular and the construction period is short.

- All equipment is automated.

- The garbage is fermented first, but the garbage does not need to be broken, and it can be directly placed on the grate for burning. The garbage can be broken by the movement of the reciprocating grate.

- Our waste incinerators are semi-installed mode, can be packed in three containers when exported, which is very convenient. Save time on installation and transport.