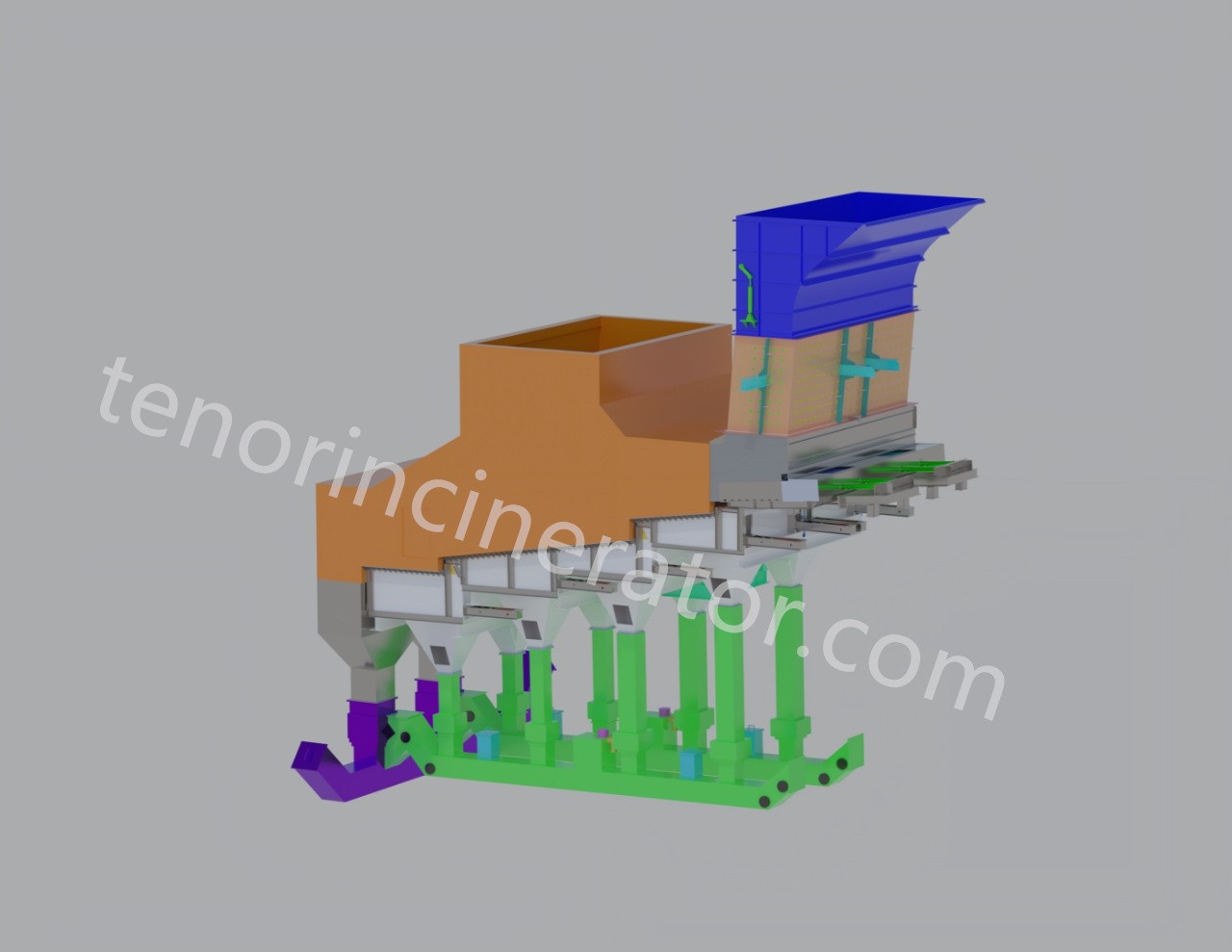

About municipal solid waste management, the MSW incineration system consists of a feeder, step grate (reciprocating grate), ash hopper, ash conveyor and slag remover , suitable for domestic garbage incineration projects with a daily processing capacity of 100~600 tons.

The garbage is fed into the hopper through a garbage crane or fuel conveyor, and is accumulated above the feeder, which is pushed into the furnace regularly. After the city garbage is put into the furnace, it passes through three stages of waste drying, solid waste burning, and waste burnout. The primary air with a certain pressure and temperature is sent into the air chamber below the grate, and passes through the garbage layer from bottom to top through the air holes on the surface of the grate and the gaps between the grates , providing heat for garbage drying and oxygen for complete combustion of garbage. The ash generated by the complete combustion of garbage enters the wet slag remover through the slag hopper and then is discharged into the slag pit. A horizontal ash leakage conveyor is connected below the air chamber, and a small amount of ash leakage from the furnace grate is sent to the wet slag remover.