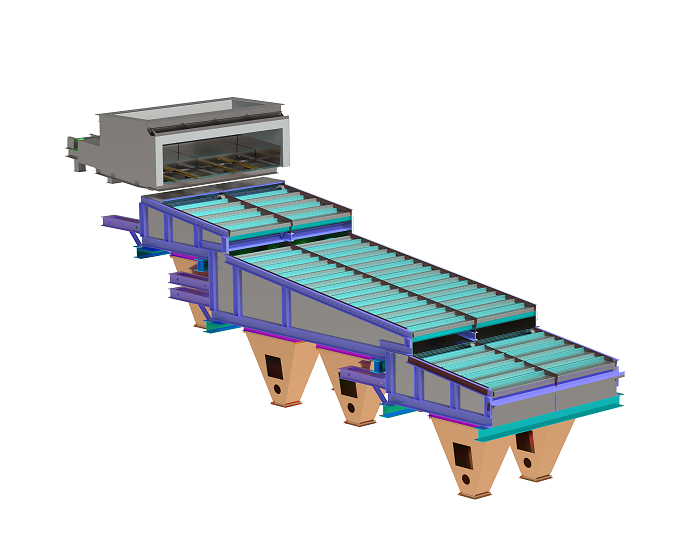

Grate Mechanical Failure

Fault phenomenon: grate stuck

Cause analysis

1. Too much feed on the grate causes the grate to be crushed: Too much feed piled on the grate exceeds its load-bearing capacity, which may cause the grate to be crushed and unable to operate normally.

2. The grate is stuck due to the broken grate: The broken grate may jam the grate, making it unable to move normally, thus causing the grate to be stuck.

3. The grate drive connecting rod and rocker seat bolts are broken or deformed, causing the grate to be stuck: If the grate drive connecting rod or rocker seat bolts are broken or deformed, it may cause the grate to be stuck, affecting the smooth operation of the grate.

4. The gap between the grate and the partition wall is too small, and the temperature change causes expansion to be blocked and stuck: If the gap between the grate and the partition wall is set too small, then when the primary air temperature changes, due to thermal expansion, the grate expansion may be blocked, causing jamming.

5. The installation gap of the guide wheels on both sides of the grate tie rod is too small, and expansion is blocked and stuck: If the installation gap of the guide wheels on both sides of the grate tie rod is insufficient, it will also cause jamming due to expansion obstruction when the temperature changes.

6. The grate roller bearing is filled with dust and cannot rotate, causing the grate resistance to increase and jam: If dust or other impurities enter the grate roller bearing, it may cause the roller to be unable to rotate normally, thereby increasing the running resistance of the grate and causing jamming.

Treatment method:

1. When operating, the operator should often check the fire on the spot to prevent the grate from being crushed by excessive feeding.

2. For the problem of grate fracture, it should be carefully checked during maintenance. If there are cracks in the grate sheet, it should be replaced in time. To check the grate sheet, the grate needs to be checked once when it is in place and once when it is out of place. During the inspection, it should be checked on the grate and in the wind chamber at the same time. During operation, control the furnace temperature of one channel well, and it is best to control the average furnace temperature at around 950℃. The furnace is not easy to coke, reducing the risk of coke falling and breaking the grate.

3. When the furnace is shut down, find a way to weld the reinforcement ribs for the parts of the grate tie rod that are prone to breakage to prevent it from breaking during operation.

4. When the furnace is shut down for maintenance, the installation of the grate drive system must be carried out strictly in accordance with the technical requirements. The boiler specialist must remember the on-site installation and maintenance requirements and technical specifications. The installation clearance and wear of the grate drive guide wheel, the wear of the roller and the wear-resistant plate, whether the roller rotates flexibly, the contact between the roller and the wear-resistant plate, and whether the grate clearance meets the requirements must be checked and confirmed in person. Maintenance is to strictly implement the three-level quality acceptance system to reduce failures during operation and ensure the normal operation of the equipment.