why choose Us ?

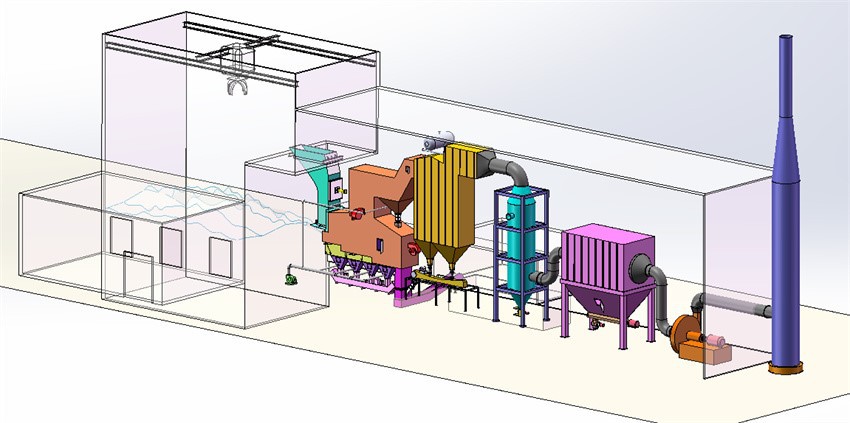

Tenor Low Carbon New Energy Technology Co., Ltd. developed a small waste incineration systems with the research team at Dalian University of Technology. WTE incineration systems include a hopper and feeding machine as well as stoker, step grates, ash hoppers, slag removal systems, transport aircraft, combustion chambers, and slag hoppers.

-

Global distribution: There are currently more than 2,100 domestic waste incineration plants around the world, with an annual incineration volume of approximately 230 million tons of domestic waste. Most of these facilities are located in developed countries.

-

Application in developed countries: Japan, the United States and Germany are the countries with the largest amount of domestic waste incineration among developed countries, with 34.9 million tons, 27 million tons and 25 million tons respectively. This shows that waste incineration is a mature waste treatment technology in these countries.

-

Growth in Europe: Between 2001 and 2015, the number of waste incineration power generation projects in Europe increased steadily, and the annual waste processing capacity increased from 52.84 million tons to 90.6 million tons, with an average annual growth rate of 7.2%. This growth is related to new regulations and standards adopted by the European Union, which have promoted the steady growth of the waste-to-energy industry.

-

Market-oriented mechanism in the United States: In the United States, the electricity price of waste incineration power generation follows the market-based electricity price mechanism, and residents need to pay garbage disposal fees, which makes the price of waste incineration disposal higher, reflecting a higher degree of marketization.

-

Global market size: It is estimated that in 2022, the global waste-to-energy industry market size will be approximately US$33.28 billion. With the advancement of global urbanization, the increase in waste generation has led to an increase in the demand for waste incineration treatment.

Products Description

The construction and development of municipal solid waste incineration plants are of great significance to deal with urban waste disposal problems. They can not only effectively reduce the amount of garbage, but also reuse resources through power generation and other methods, and also help improve the ecological environment quality of the city. However, the construction and operation of waste incineration plants also need to take into account environmental standards to ensure the harmlessness of emissions, and take corresponding measures to reduce possible air pollution.

Products Parameters

|

Scale (t/d) |

Number of furnaces |

Overall height of equipment (m) |

Floor space (m2) |

Emission standard |

|

50 |

1 |

17 |

60 |

《Pollution control standards for household waste incineration》 (GB18485-2014) |

|

100 |

1 |

17 |

75 |

|

|

150 |

2 |

17 |

90 |

|

|

200 |

2 |

17 |

105 |

|

|

250 |

3 |

17 |

12 |

Main equipment

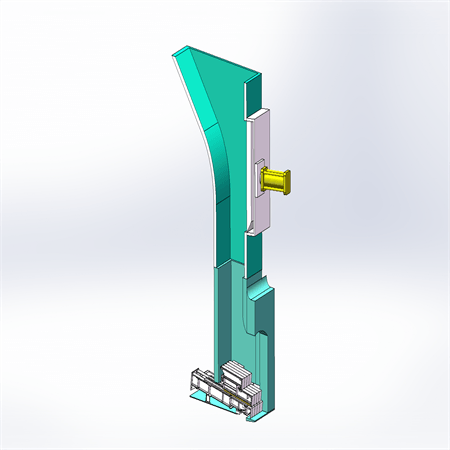

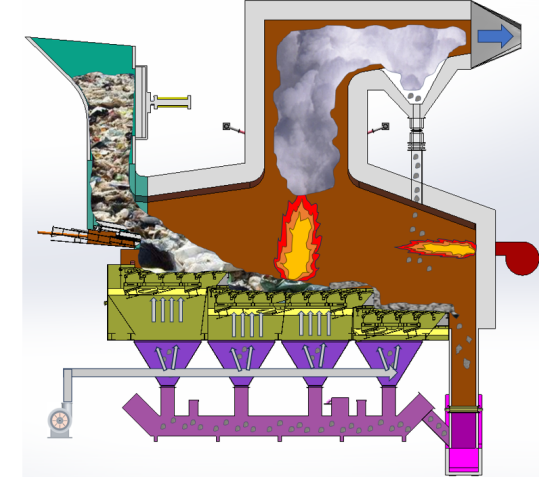

Feeding system

A gate is located inside the feeder. The feeding system consists of a hopper, a feeder and a gate. Gates are used to seal the hopper and also break the bridge of garbage. The "bridge" can be broken by moving the gate when there is a blockage. Hydro-cylinders drive the gate and feeder, which can be adjusted to feed according to incinerator load.

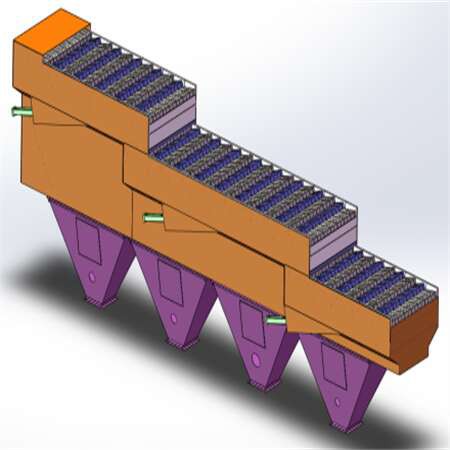

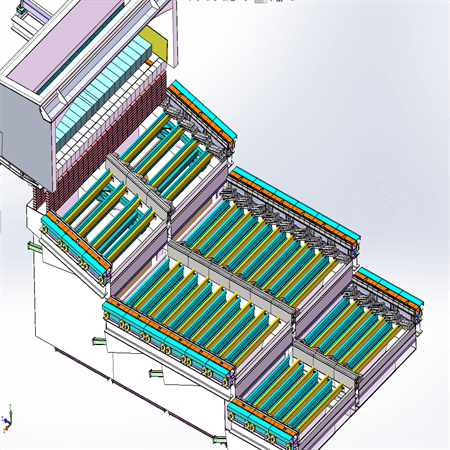

Fire grate

The compact incinerator for municipal waste made by Tenor adopts the horizontal step reciprocating grate. It is divided into 3 stages: drying, burning, and burning-out zone. After falling down, garbage is spread out and the garbage is moved to avoid incomplete combustion. Hydro-cylinder drives the reciprocating grate. The three sections can be independently controlled, and grate cycle can be adjusted based on the state of combustion in the furnace. It is constructed of high-temperature resistant cast steel that has excellent wear resistance.

Grate advantages:

High efficiency stable combustion:

The garbage is fully burned, the thermal ignition reduction rate is low,Equipment performance: The grate has good wear resistance, high temperature resistance and corrosion resistance, low damage rate, low replacement frequency and low maintenance cost.The pores and gaps are matched with air inlet, and the overall air inlet effect is more uniform, which is conducive to uniform combustion and stable combustion.

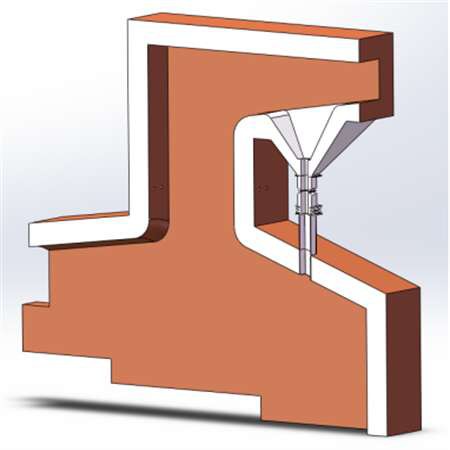

Incinerator

The side walls and front and back arches of the combustion chamber are constructed from castable material, thermal insulation cotton and refractory bricks. The walls of the furnace are constructed with castable material, thermal insulation cotton and refractory blocks. The front and back arch structures are adjusted based on the incinerator's traditional structure to increase heat transmission from the front to rear arch. This accelerates the drying of waste and ignition of it.

In comparison with the vertical chimney, the secondary combustion chamber has been arranged horizontally. This reduces both the height and the cost of construction . The secondary combustion chamber also uses a Spiral Separation system and a Tesla valve principle, which allows 90% of fly ash to be sent back into the primary combustion room and then enter the wet-slag removal device. Reduce the amount of fly ash contained in the flue gases of the incinerator's outlet.

Solid waste incinerator process flow

Following the garbage in the furnace, the three sections: burning, drying and burning out are carried out with certain temperature and pressure. Following the trash into the furnace, the three sections are: burning, drying and burning off, under a pressure and temperature.

The ash from the combustion of garbage is pumped into the wet-slagging machine via the slagging bucket, and the remainder goes to the slag pit. The horizontal conveyor for ash leakage is attached under the air-chamber, and small amounts of slag and ash under the grates are then sent to the machine that removes wet slag.

The combustion flue gas enters through the throat into the second combustion chamber. Secondary air is then added in the throat for the purpose of adjusting the furnace's temperature, ensuring complete combustion, and controlling the production of nitrogen dioxides.

It is possible to choose between hot water, steam, or electricity production according to project size and cost benefits. Deacidification of the flue gas is done after it has been cooled by heat transfer.

Process charateristics

- Easy installation, simple structure;

- Automate all equipment; reduce the workload of furnace personnel

- Construction costs are low and the total height of buildings is small.

- Secondary combustion chambers adopt a spiral dust-removal structure with a Tesla valve in order to reduce fly ash contents, lower the cost of dust removal, and increase the life expectancy.

- Heat burn is reduced by less than 5 %.

- Emissions of pollutants meet standard.

- Turn-key turnkey WTE and customized complete proposals.

Waste to energy project display

garbage incinerator 50 tons/d

Benefite of Waste Management

MSW incinerator can produce steam, hot water and electricity generation, sustainable Power from Small-Scale Waste Incineration.

Application:Township, cities and towns, government, power plant.

FAQ

Q: What is municipal solid waste incinerator?

Q: What is involved in incineration of municipal waste?

Q: what is the working principle of solid waste incineration?

Q: What is an example of municipal solid waste?