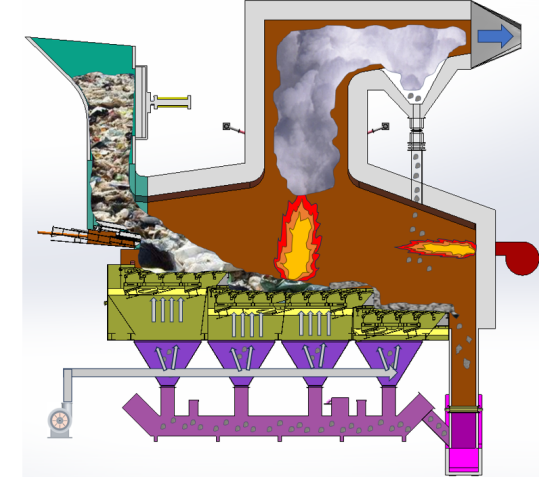

Incinerators with moving grate are also known as municipal waste incinerators. A waste crane is used to introduce the waste through the "throat", at the one end of grate. From there, it proceeds down the descending grate and into the ash pit on the other end. The ash is then removed by a waterlock.

why choose Us ?

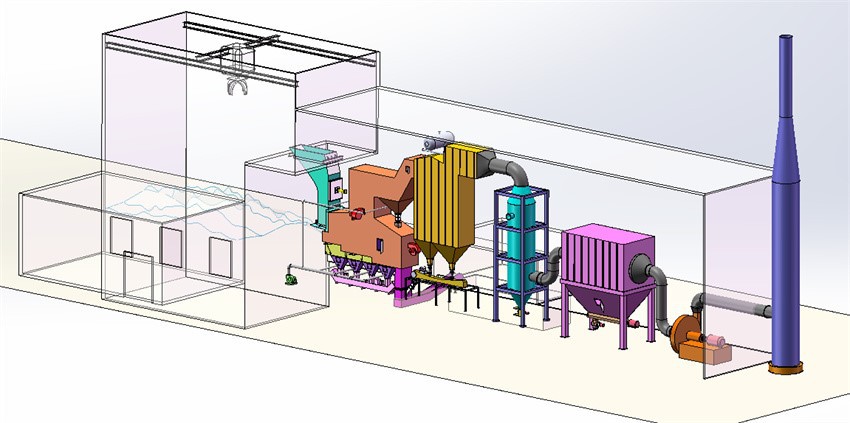

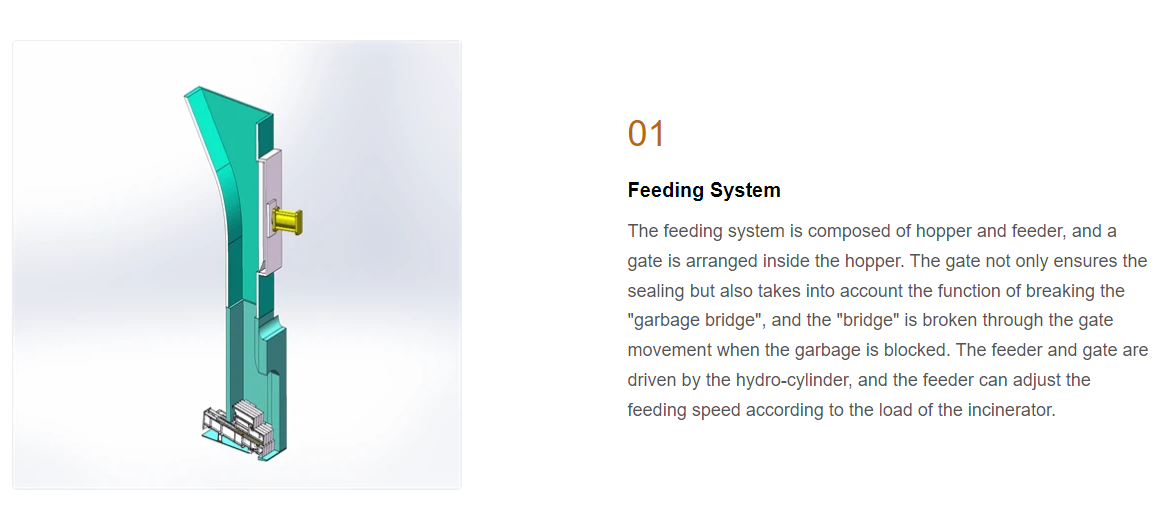

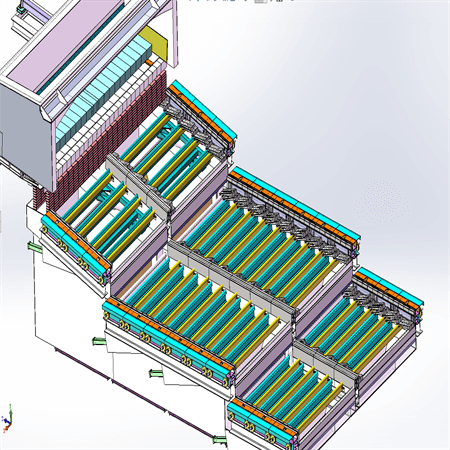

Tenor Low Carbon New Energy Technology Co., Ltd. developed a small waste incineration systems with the research team at Dalian University of Technology. WTE incineration systems include a hopper and feeding machine as well as stoker, step grates, ash hoppers, slag removal systems, transport aircraft, combustion chambers, and slag hoppers.

Moving grate incinerators are used in industrial and municipal waste treatment facilities to burn solid waste materials such as garbage, sludge, and industrial waste. They are commonly found in waste-to-energy plants, where the heat generated from the incineration process is used to produce electricity. These incinerators are also used in cement kilns, steel mills, and other industrial processes that require high temperatures for processing or production.

Products Description

The construction and development of municipal solid waste incineration plants are of great significance to deal with urban waste disposal problems. They can not only effectively reduce the amount of garbage, but also reuse resources through power generation and other methods, and also help improve the ecological environment quality of the city. However, the construction and operation of waste incineration plants also need to take into account environmental standards to ensure the harmlessness of emissions, and take corresponding measures to reduce possible air pollution.

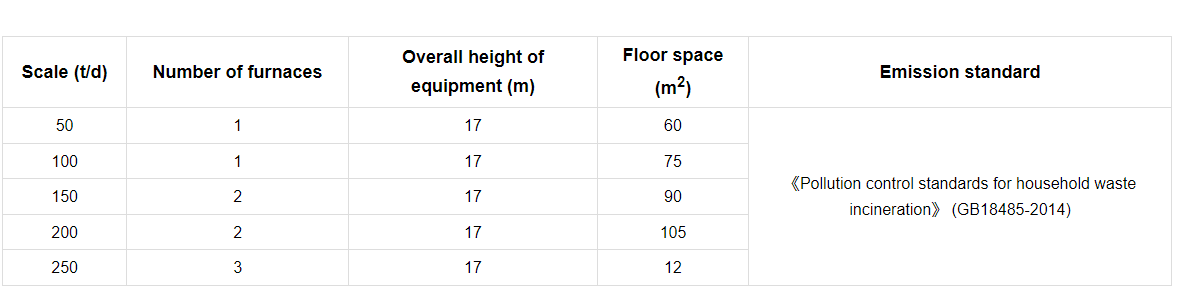

Products Parameters

Main equipment

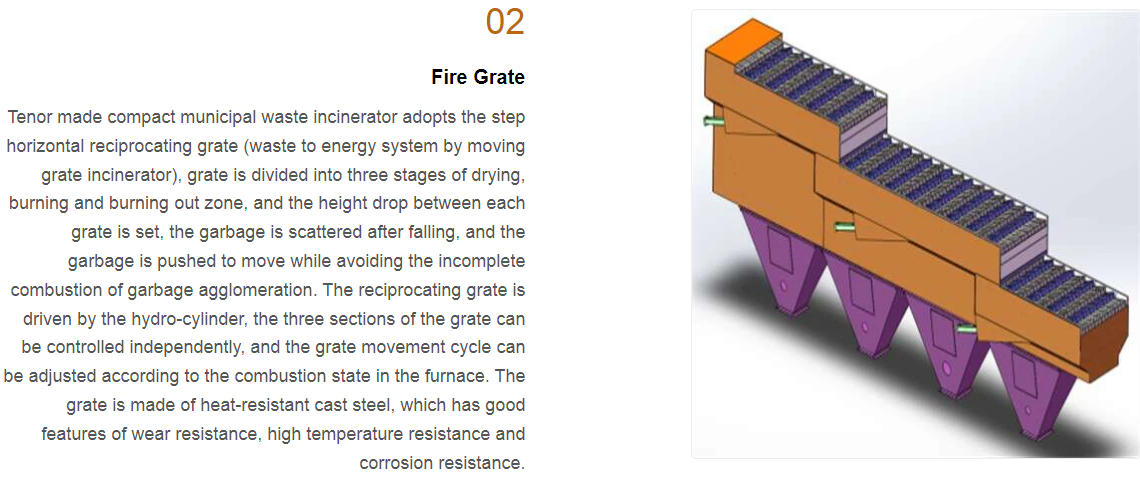

Grate advantages:

High efficiency stable combustion:

The garbage is fully burned, the thermal ignition reduction rate is low,Equipment performance: The grate has good wear resistance, high temperature resistance and corrosion resistance, low damage rate, low replacement frequency and low maintenance cost.The pores and gaps are matched with air inlet, and the overall air inlet effect is more uniform, which is conducive to uniform combustion and stable combustion.

Solid waste incinerator process flow

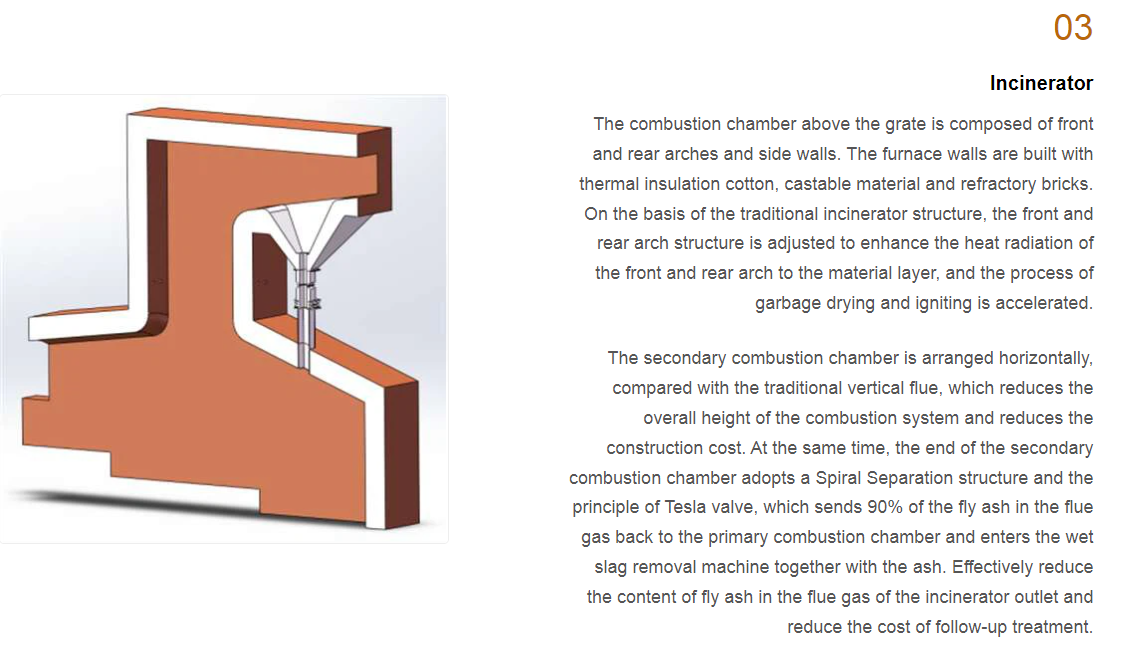

- After the garbage into the furnace through three sections of the grate: drying, burning, burning out, with a certain pressure and temperature. The garbage is pushed into the furnace in three sections: drying, burning and burning out, at a specific temperature and pressure.

- The ash generated by complete combustion of garbage is fed into the wet slagging system through the slagging hopper and then deposited in the slag pit. The horizontal ash leakage conveyer is connected below the air chamber. A small amount of ash under the grate will be sent to the wet removal machine.

- The secondary combustion chamber is entered by the flue gas from the combustion. Secondary air is then added to the chamber at the throat in order to control nitrogen oxides, adjust furnace temperature and ensure complete combustion.

- The secondary combustion chamber temperature is between 850 and 1050 degrees Fahrenheit. The flue gas remains in the secondary chamber combustion chamber for at least 2 seconds, after which it exits the system. The user can choose from a variety of waste heat utilization options, including hot water production, power generation, and steam production, depending on the size and economic benefit of the project. After heat transfer, the cooled flue gases are discharged through deacidification and filtration.

Process charateristics

- Easy installation, simple structure;

- Automate all equipment; reduce the workload of furnace personnel

- Construction costs are low and the total height of buildings is small.

- Secondary combustion chambers adopt a spiral dust-removal structure with a Tesla valve in order to reduce fly ash contents, lower the cost of dust removal, and increase the life expectancy.

- Heat burn is reduced by less than 5 %.

- Emissions of pollutants meet standard.

- Turn-key turnkey WTE and customized complete proposals.

Waste to energy project display

garbage incinerator 50 tons/d

Benefite of Waste Management

MSW incinerator can produce steam, hot water and electricity generation, sustainable Power from Small-Scale Waste Incineration.

Application:Township, cities and towns, government, power plant.

Everything You Need to Know

What is the temperature of moving grate incinerator?

The temperature of the waste is +/-950 degrees Celcius. The retantion period is between 45 minutes and 1 hour. After the combustion, there are two types of residues: the ash and the residual waste. The ash is about +/-10% the original volume. Flue gases at high temperatures.

Why are incinerators controversial?

Incinerators also emit a variety of pollutants and toxins that can harm the local air quality. The emissions include dioxins and NOx, as well as ultrafine particulate material that can harm both the environment and human health.

Is burning waste better than landfill?

Landfills are affordable and offer the potential of energy recovery. However, they also come with environmental concerns like methane emission and contamination risks. Incineration is a way to reduce waste and destroy hazardous material, but it also requires strict emission control and monitoring.

What is the minimum temperature for an incinerator?

The incinerator's minimum temperature depends on both the waste type and the destruction efficiency desired. Most modern incinerators are operated at temperatures between 1,382degF and 2,012degF. These temperatures are ideal for destroying organic material and reducing harmful pollutants like dioxins or furans. The actual minimum temperature can vary depending on local laws and environmental standards.