who choose us?

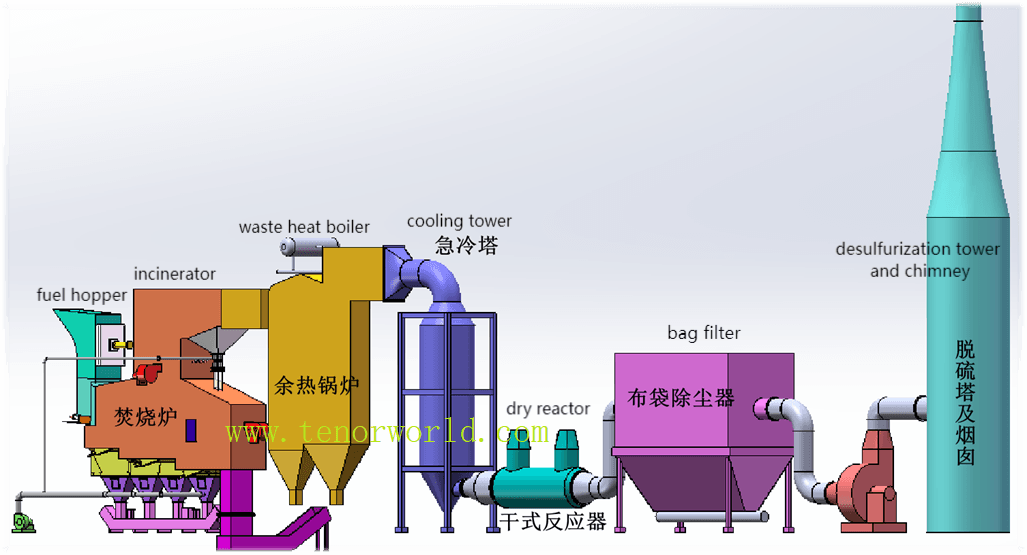

Tenor Low Carbon new Energy Technology (Liaoning) Co., Ltd. was established in 2021 and registered at the Industrial Incubation Base of Dalian University of Technology. Through cooperation with thermal power departments, environmental departments, mechanical departments, inorganic materials and other disciplines of HIT and Dalian University of Technology, the company focuses on designing and developing complete sets of small urban waste incineration technologies; Focusing on the application of technologies such as furnace arches, modular assembly, and dust reduction and dioxin removal inside the furnace to ensure full combustion of waste.

one-stop solution

professional team

high quality

paramenters of Municipal Solid Waste Incinerator

|

Scale (t/d) |

Number of furnaces |

Overall height of equipment (m) |

Floor space (m2) |

Emission standard |

|

50 |

1 |

17 |

60 |

《Pollution control standards for household waste incineration》 (GB18485-2014) |

|

100 |

1 |

17 |

75 |

|

|

150 |

2 |

17 |

90 |

|

|

200 |

2 |

17 |

105 |

|

|

250 |

3 |

17 |

12 |

As a professional garbage incinerator manufacturer, we have strict quality management requirements for our products. For the level of the burning room and the remaining heat boiler, our waste incineration furnace has its unique advantages:

- Structural simplification: The horizontally arranged combustion chamber and waste heat boiler can simplify the structural design and reduce complexity, thereby reducing manufacturing and installation costs.

- Space utilization: Horizontal arrangement helps to utilize space more efficiently, especially under limited site conditions, and can reduce the floor area.

- Ease of maintenance: Equipment arranged horizontally is easier to maintain and service as they are generally more accessible, which can reduce maintenance costs.

- Thermal efficiency: The horizontal arrangement of waste heat boilers can optimize the recovery and utilization of heat energy and improve the thermal efficiency of the entire system.

- Cost-effectiveness: By optimizing the design, the amount of material used can be reduced, and manufacturing and transportation costs can be reduced.

- Safety: In some cases, a horizontal arrangement may help improve the safety of the system because it reduces the vertical height of hot components, thereby reducing heat loss and potential safety risks.

If you are interested in our products, you can contact us directly.