| Type | Food Waste Disposer |

| Warranty | 1.5 years |

| Material | Based on customer needs |

| Weight (kg) | 5000 |

| Power | Based on customer needs |

| Place of origin | Liaoning, China |

| Brand name | Tenor |

| Model number | 100t/day |

| Machinery test report | Provided |

| Video outgoing-inspection | Provided |

| Core components | Pump, Engine, Gearbox |

| Product name | Household Waste Incinerator |

| Certification | ISO9001 |

| Application | Solid Waste |

| Function | Waste Treatment |

| Fuel | Solid Waste Garbage |

| Capacity | 100T/Day |

| Feature | Eco-friendly and High efficiency |

| Warranty | 1 Year Warranty |

| Usage | power Waste Incinerator Power Plant Waste Burning Equipment |

| Keywords | Waste Treatment Machinery Refuse Collector |

| NO | Equipment Name | Technical Specification | Material | Quantity | ||

| Common | Spare | Total | ||||

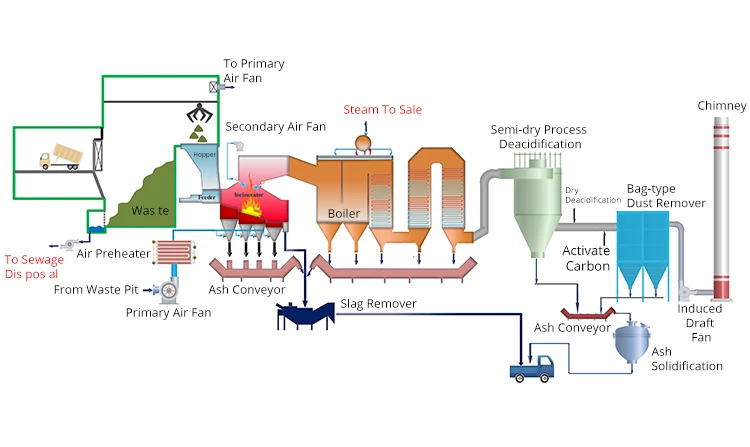

| 1.Waste feeding and receiving system | ||||||

| 1 | Garbage Hopper | Form: Angle type (including hopper gate) | CS,SUS | 1 | 0 | 1 |

| Effective volume: 10m³ | ||||||

| Operation mode: remote / on-site control | ||||||

| 2 | Feeders | Form: hydraulic drive type | CS,SUS | 1 | 0 | 1 |

| Capacity: 3t/h | ||||||

| Operation mode: remote / on-site control | ||||||

| 2.Incinerator systems | ||||||

| 3 | Grate | Form:Horizontal reciprocating grate Performance: 3t/h | Heat-resistant cast steel | 1 | 0 | 1 |

| Driving form: hydraulic drive | ||||||

| Operation mode: remote / on-site control | ||||||

| Length: 7.235m | ||||||

| Width: 1.712m | ||||||

| Effective area of furnace bed: 12.386 ㎡ | ||||||

| 4 | Incinerator housings | Includes internal insulation materials | CS | 1 | 0 | 1 |

| 5 | Under-furnace ash hopper | Form: steel plate welded parts | CS | 3 | 0 | 3 |

| 6 | Slag chute | Form: steel plate welded parts | CS | 1 | 0 | 1 |

| 3.Hydraulic system | ||||||

| 7 | Hydraulic equipment | Common/maximum pressure: 9/15Mpa | Assembly | 2 | 0 | 2 |

| 8 | Hydraulic Cylinders | / | Assembly | 8 | 1 | 9 |

| 9 | Hydraulic System Pipes & Fittings | / | SUS | 1 set | 0 | 1 set |

| 4.Slag removal system | ||||||

| 10 | Slag Remover | Form: water seal slag remover Material: ash | CS | 1 | 0 | 1 |

| Operation mode: remote / site control | ||||||

| Capacity: Maximum 1t/h | ||||||

| 11 | Dust Leakage Conveyor | Form: Belt Conveyor Material: ash | CS | 1 | 0 | 1 |

| Capacity: 0.3t/h | ||||||

| 5.Combustion system | ||||||

| 12 | Burners | Form: One-piece | Assembly | 2 | 0 | 2 |

| Operation mode: remote/field | ||||||

| Control Fuel: light diesel oil | ||||||

| Capacity: 150kg/h | ||||||

| 13 | Ventilator | Form: centrifugal | Assembly | 1 | 0 | 1 |

| Operation mode: remote / on-site control | ||||||

| Capacity: 12000Nm³/h | ||||||

| 14 | Air duct | / | CS | 1 | / | 1 |

| 15 | Flow meters, valves, thermocouples, sensors, etc. | Domestic | Assembly | / | / | / |

1.Q: Can you give us a quotation right now?

A: We can quote the grate standard spare parts, but for the full set grate stokers are all customized. Please give us your required dimension of grate capacity. Then we will make a design and quotation for you ASAP.

2. Q: Can you give us your price list?

A: Sorry, we don't have any. Our products are all manufactured according to customers' requirements . If necessary, we can send our latest grate wearing spare parts price list.

3. Q: What is your MOQ?

A: 1 piece/set.

4. Why Should You Buy From Us Not From Other Suppliers?

We Have 26 Years Experience Of Manufacturing Grate Stokers For Boiler Companies. Mould Design+welding+machining+precision Castings.We Have Five Workshops And Three Casting Plant, Advanced -equipped Two Denmark Disa Casting Lines, Shell Casting Etc.

5. Q: Do you accept a special order?

A: Yes, we do. We can manufacture all kinds of casting products and grate, according to your technical drawings and required material.

6. Q: Can you give us the technical drawing and data?

A: We will give you the overall dimension drawing for your plan and project. But the detailed drawing and data will be sent you after we signed the contract and confidentiality agreement.

7. Q: Do you provide after-sales service?

A: Yes, we do. Our products are guaranteed for the wearing parts one year.

8. Q: Can your engineer come to our place for installation guide?

A: Yes, we can. We will provide a video and document for installation. And if necessary, we have professional installation team with rich experience, we can send our engineers oversea for installation guide.

9. How can we guarantee quality?

Always a pre-production sample before mass production; Always final Inspection before shipment;