A Small Garbage Incinerator is a type of waste disposal system designed for small-scale applications such as individual homes, small communities, or remote locations where access to centralized waste management facilities is limited. These incinerators are typically smaller and less complex than their larger counterparts used by municipalities or industrial facilities.

why choose Us ?

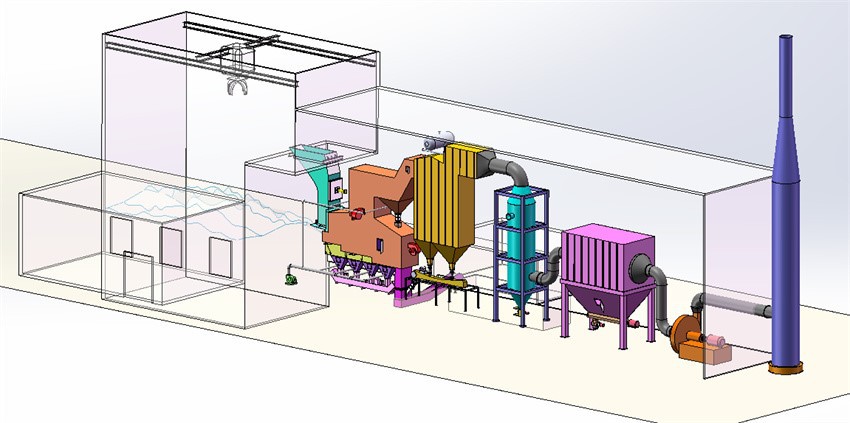

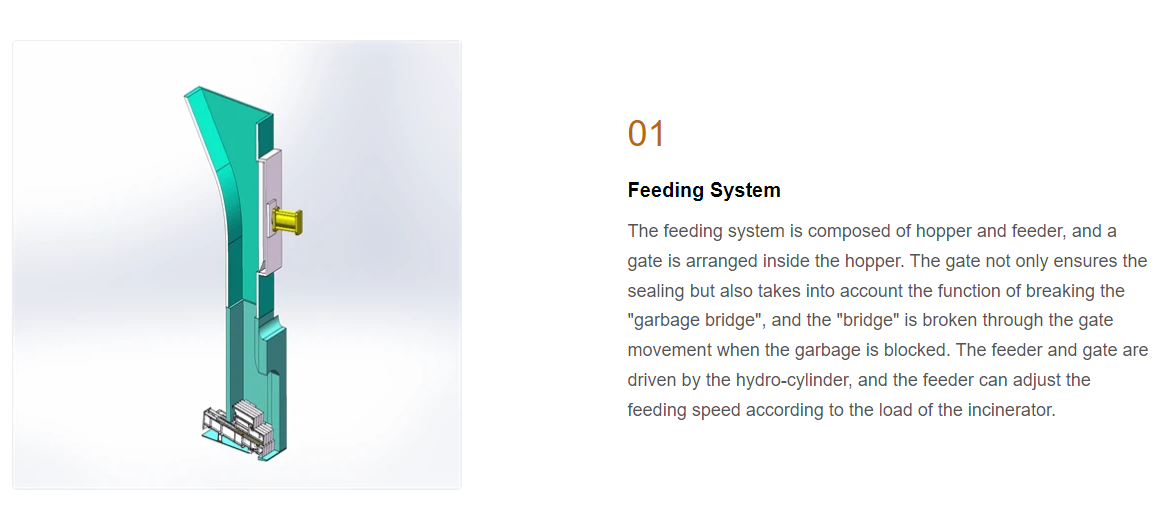

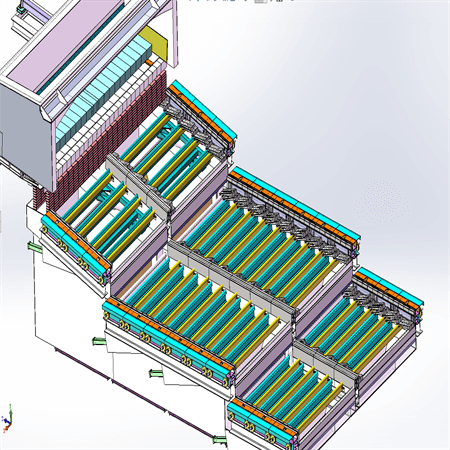

Tenor Low Carbon New Energy Technology Co., Ltd. developed a small waste incineration systems with the research team at Dalian University of Technology. WTE incineration systems include a hopper and feeding machine as well as stoker, step grates, ash hoppers, slag removal systems, transport aircraft, combustion chambers, and slag hoppers.

The small garbage incinerators are designed to burn household waste such as kitchen scraps, paper and cardboard. These units can be portable or installed permanently on a home. Small Garbage Incinerators are typically made up of:

1. Feeding mechanism: A simple loading chute or door through which waste is fed to the incineration chamber.

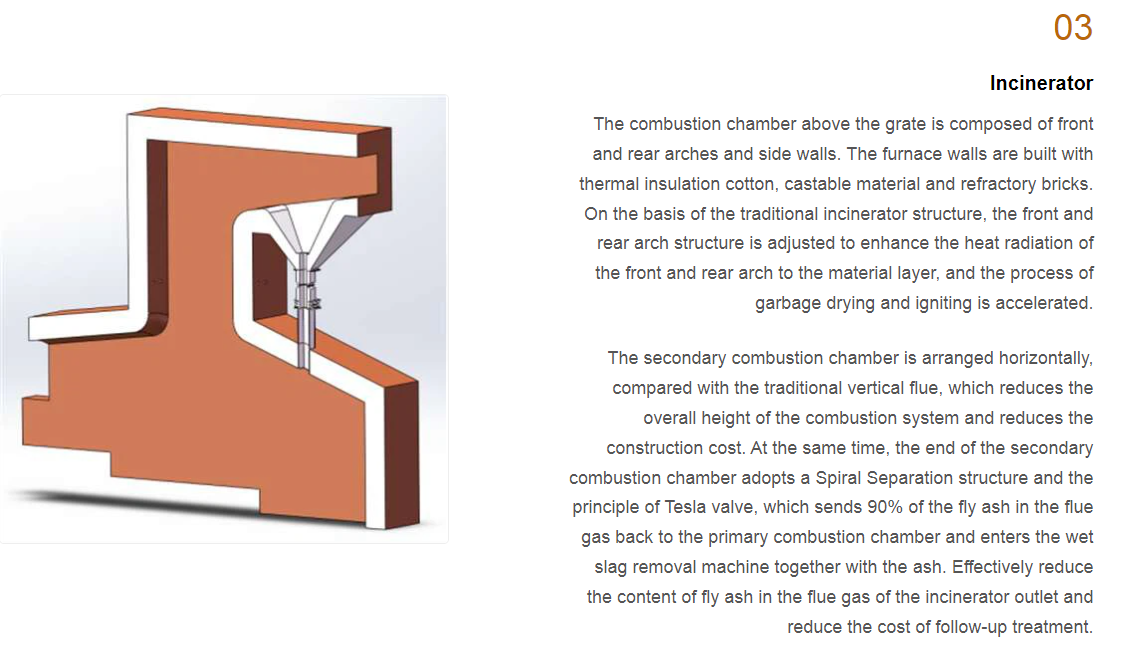

2. Combustion Chamber (also called combustion chamber): This is the chamber in which wastes are burned. The combustion chamber is designed to maximize the amount of material that is burned by ensuring efficient combustion at high temperature.

3. Heat Recovery (optional). Some small incinerators have a system that can recover the heat produced by combustion. This energy can then be used to heat water or for space heating.

4. Small incinerators can be equipped with basic emission control systems such as filters or scrubbers that capture particulates and reduce harmful gas emissions.

5. Ash Removal: The ash and residue left after combustion must be collected, and properly disposed. It could be a simple ashpan that is easily removed and cleaned.

6. Control System: Small units can have a simple control system that monitors temperature and ensures safe operation.

Small Garbage Incinerators are an environmentally-friendly and convenient way to reduce waste volume that would otherwise be disposed of in landfills. They also require responsible maintenance and use to avoid pollution and comply with local regulations. If not controlled properly, the emissions from these incinerators can contribute to air pollutants and health risks. It is therefore important to adhere to all local laws and operating guidelines when using a small garbage incinerator.

Products Description

The construction and development of municipal solid waste incineration plants are of great significance to deal with urban waste disposal problems. They can not only effectively reduce the amount of garbage, but also reuse resources through power generation and other methods, and also help improve the ecological environment quality of the city. However, the construction and operation of waste incineration plants also need to take into account environmental standards to ensure the harmlessness of emissions, and take corresponding measures to reduce possible air pollution.

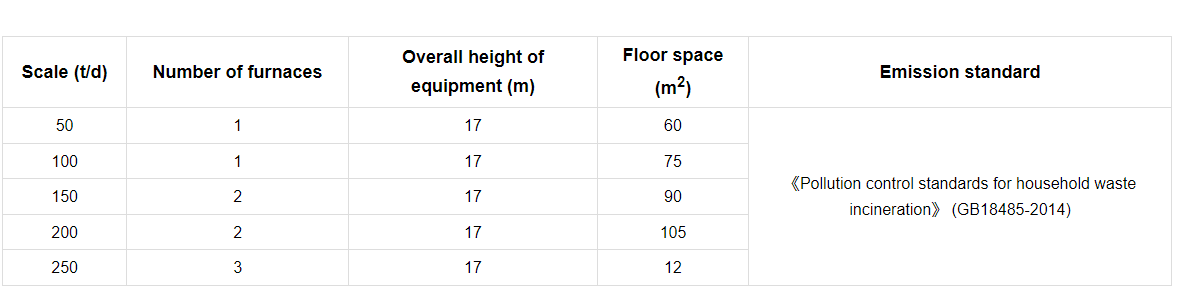

Products Parameters

Main equipment

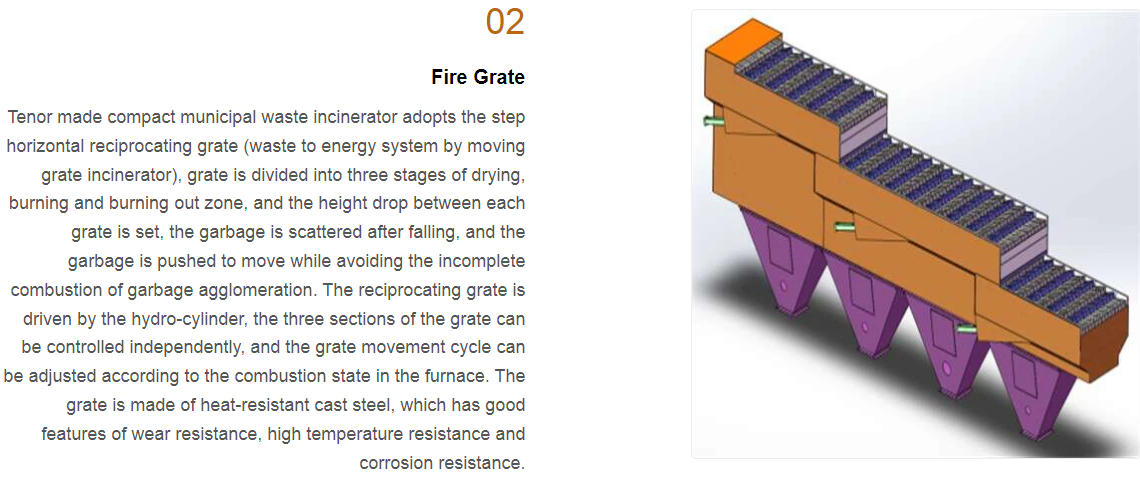

Grate advantages:

High efficiency stable combustion:

The garbage is fully burned, the thermal ignition reduction rate is low,Equipment performance: The grate has good wear resistance, high temperature resistance and corrosion resistance, low damage rate, low replacement frequency and low maintenance cost.The pores and gaps are matched with air inlet, and the overall air inlet effect is more uniform, which is conducive to uniform combustion and stable combustion.

Solid waste incinerator process flow

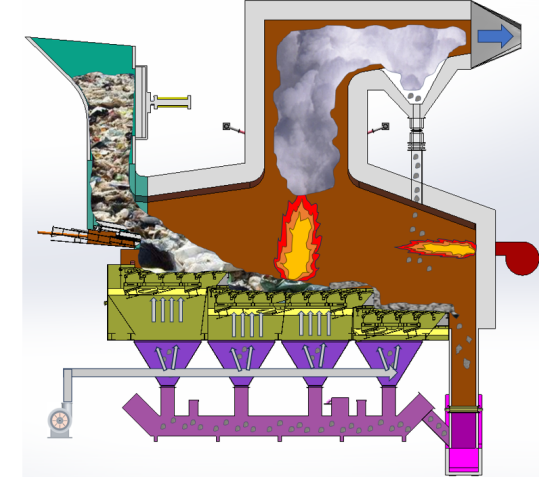

Following the garbage in the furnace, the three sections: burning, drying and burning out are carried out with certain temperature and pressure. Following the trash into the furnace, the three sections are: burning, drying and burning off, under a pressure and temperature.

The ash from the combustion of garbage is pumped into the wet-slagging machine via the slagging bucket, and the remainder goes to the slag pit. The horizontal conveyor for ash leakage is attached under the air-chamber, and small amounts of slag and ash under the grates are then sent to the machine that removes wet slag.

The combustion flue gas enters through the throat into the second combustion chamber. Secondary air is then added in the throat for the purpose of adjusting the furnace's temperature, ensuring complete combustion, and controlling the production of nitrogen dioxides.

It is possible to choose between hot water, steam, or electricity production according to project size and cost benefits. Deacidification of the flue gas is done after it has been cooled by heat transfer.

Process charateristics

- Easy installation, simple structure;

- Automate all equipment; reduce the workload of furnace personnel

- Construction costs are low and the total height of buildings is small.

- Secondary combustion chambers adopt a spiral dust-removal structure with a Tesla valve in order to reduce fly ash contents, lower the cost of dust removal, and increase the life expectancy.

- Heat burn is reduced by less than 5 %.

- Emissions of pollutants meet standard.

- Turn-key turnkey WTE and customized complete proposals.

Waste to energy project display

garbage incinerator 50 tons/d

Benefite of Waste Management

MSW incinerator can produce steam, hot water and electricity generation, sustainable Power from Small-Scale Waste Incineration.

Application:Township, cities and towns, government, power plant.

FAQ

Q: What are the three types of incinerators?

Q: What is the best type of incinerator?

Q: What are the examples of incinerators?

Q: What are the different types of incinerator?